Structure and Principle

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for Factory making China High Quality Gypsum Powder Production Machine, Welcome any of your respective inquiries and concerns for our products and solutions, we look ahead to establishing a long-term business marriage with you within the in the vicinity of long run. contact us today.

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for China High Quality Gypsum Powder Production Machine, Gypsum Powder Production Machine, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do specialist solutions.

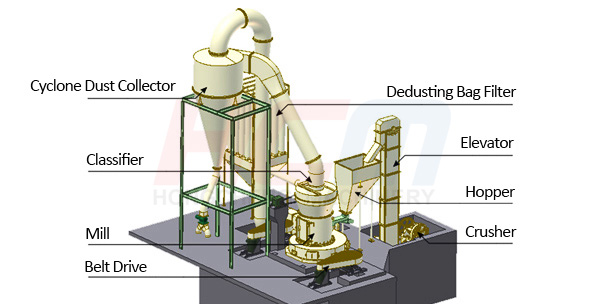

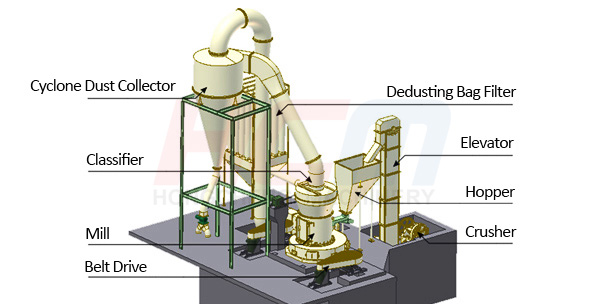

R-series roller mill is mainly composed of main mill, analysis machine, blower, bucket elevator, jaw crusher, electromagnetic vibrating feeder, electric control motor, finished cyclone separator and pipeline equipment, etc.

As the mill works, centrifugal force drives the rolls against the inner vertical surface of the grinding ring. Plows rotating with the assembly lift ground material from the mill bottom and direct it between the rolls and the grinding ring where it is pulverized. Air enters from below the grind ring and flows upward carrying fines to the classifying section. The classifier allows the sized material to pass to the product collector and returns unqualified oversized particles to the grinding chamber for further processing. The mill operates under negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the service life of major mechanical components.

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for Factory making China High Quality Gypsum Powder Production Machine, Welcome any of your respective inquiries and concerns for our products and solutions, we look ahead to establishing a long-term business marriage with you within the in the vicinity of long run. contact us today.

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for Factory making China High Quality Gypsum Powder Production Machine, Welcome any of your respective inquiries and concerns for our products and solutions, we look ahead to establishing a long-term business marriage with you within the in the vicinity of long run. contact us today.

Factory making China High Quality Gypsum Powder Production Machine, Gypsum Powder Production Machine, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do specialist solutions.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for Factory making China High Quality

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we’re devoted to supplying the top benefit for our customers for Factory making China High Quality