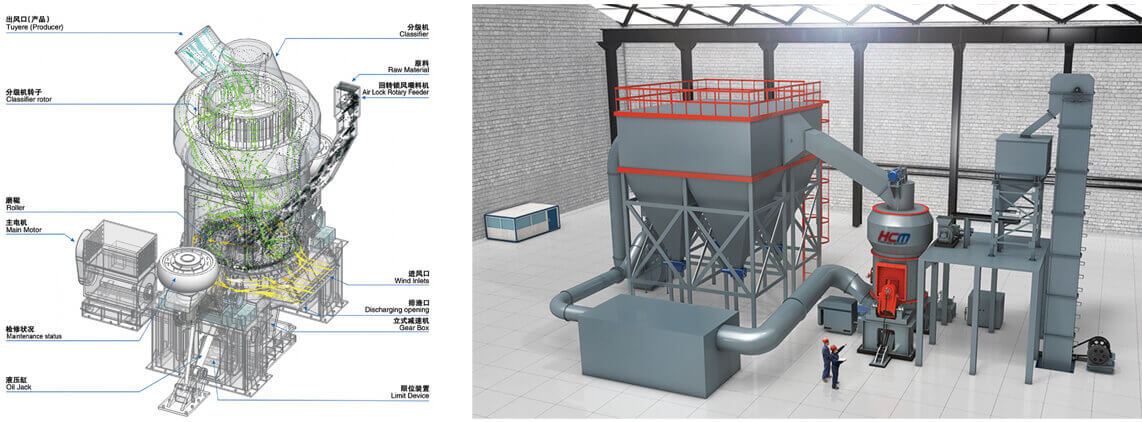

Structure and Principle

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Good Quality Vertical/Horizental Planetary Ball Mill Machine for Grinding Powder, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for China Planetary Ball Mill and Nano Ball Mill, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

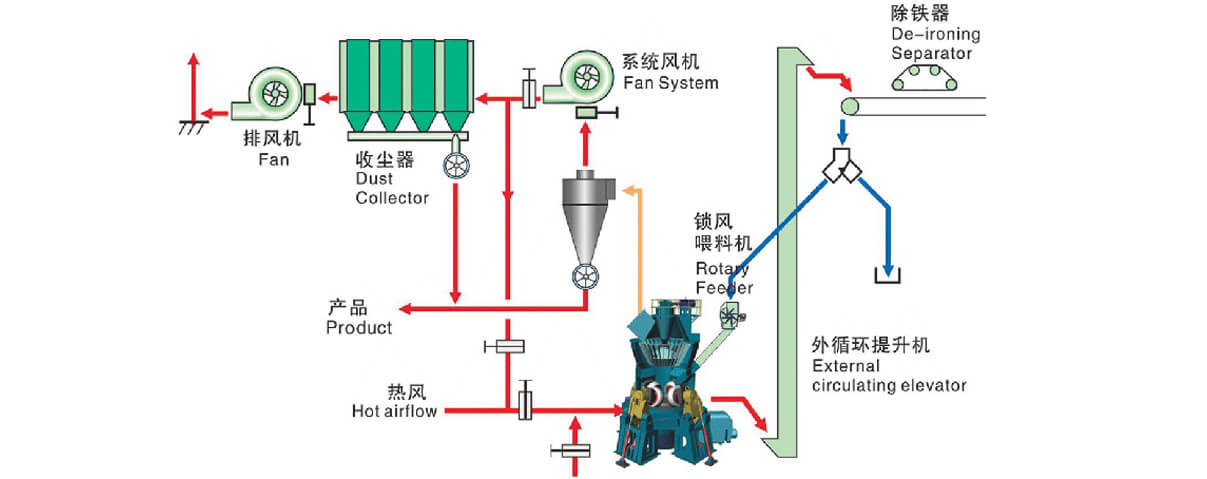

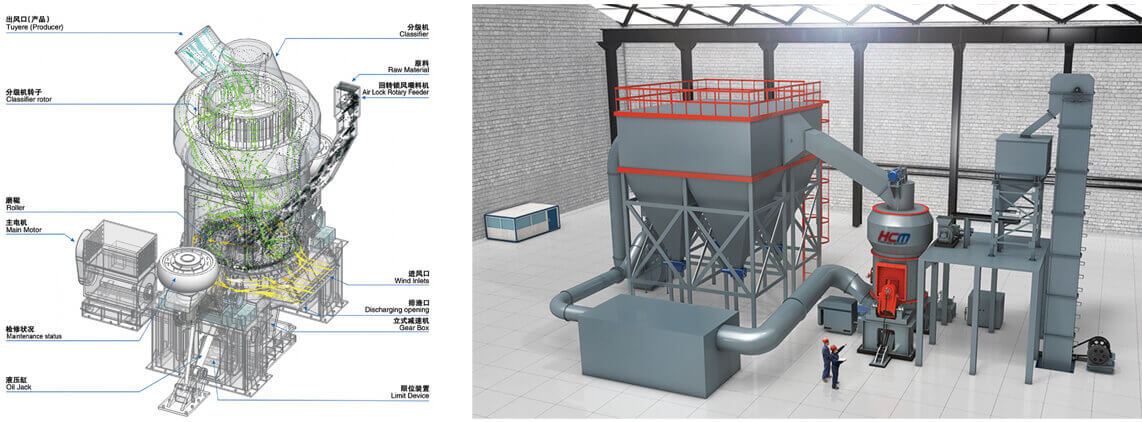

As the vertical roller mill works, the motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and pulverized through squeezing, grinding and cutting. Simultaneously, the hot air is blew up around the dial and brow up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

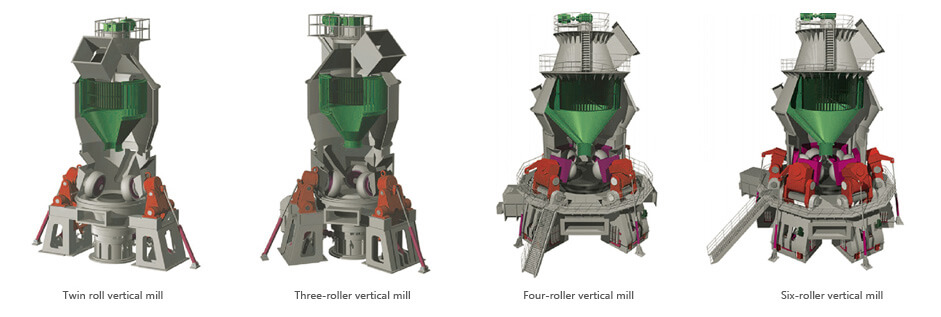

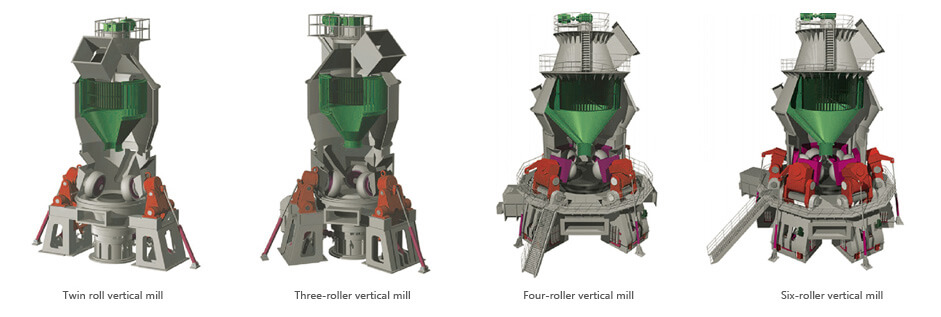

HLM vertical roller mill using standard modules to design and fabricate pressurization device. As the capacity increases, the roller numbers will increase (we can use 2, 3 or 4, maximum 6 rollers ) in proper permutation and combination to set different series of equipment with different capacities by minimum standard parts to meet the requirements of different materials, fineness and outputs.

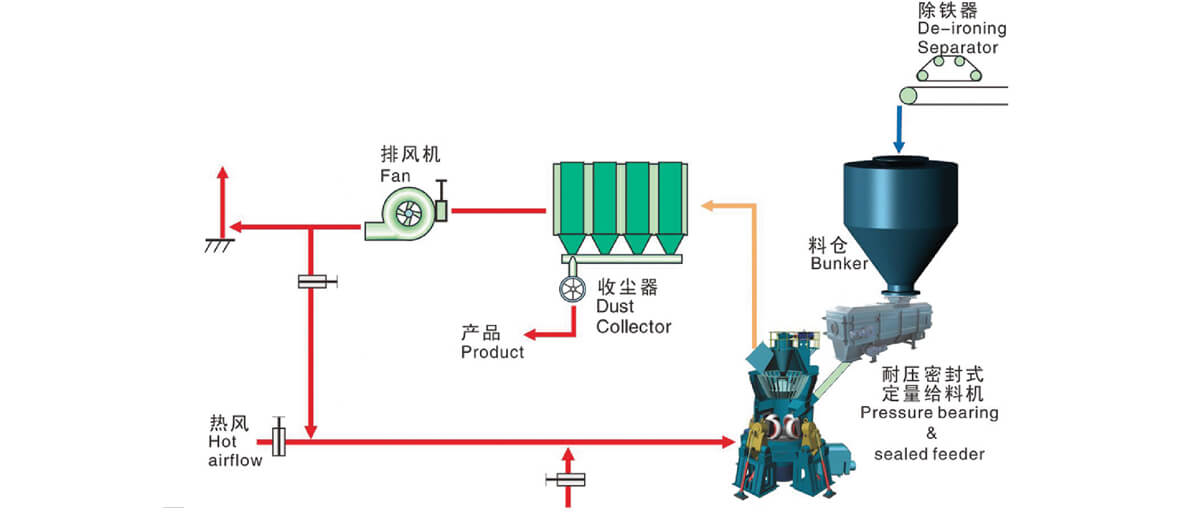

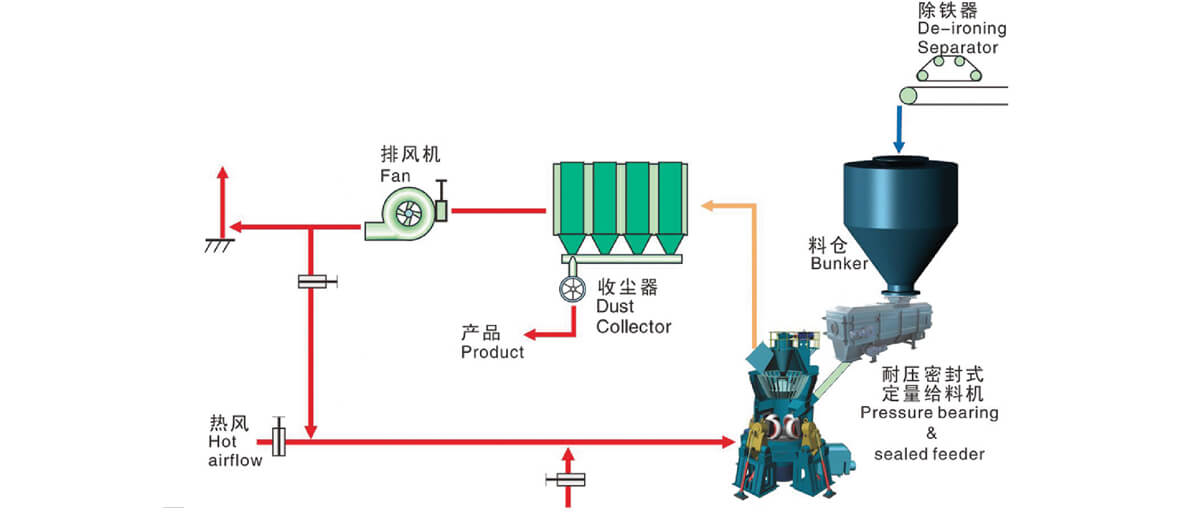

Unique Dust Collection System I

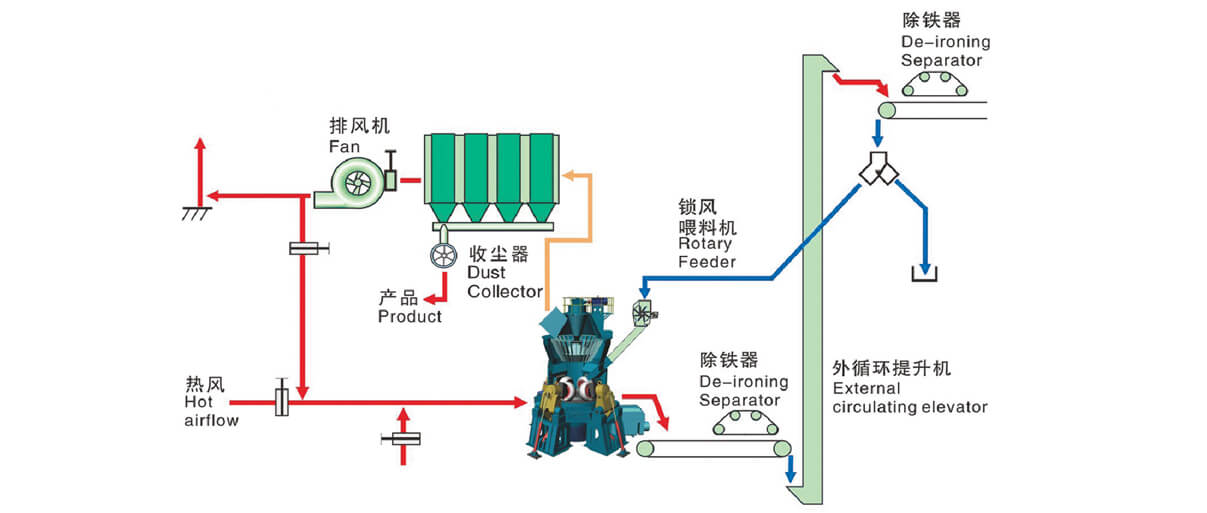

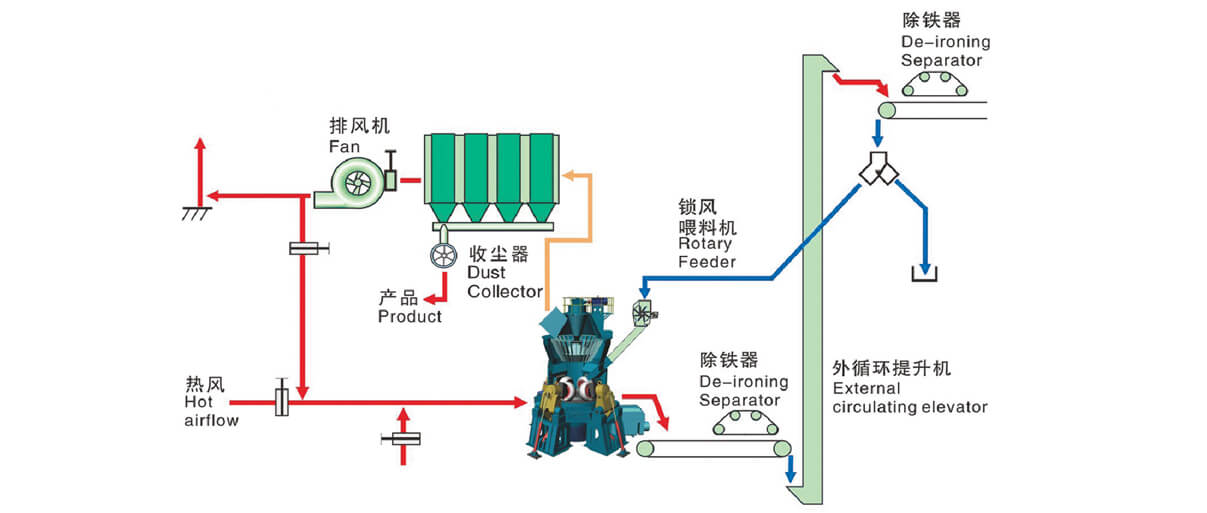

Single dust collection system II

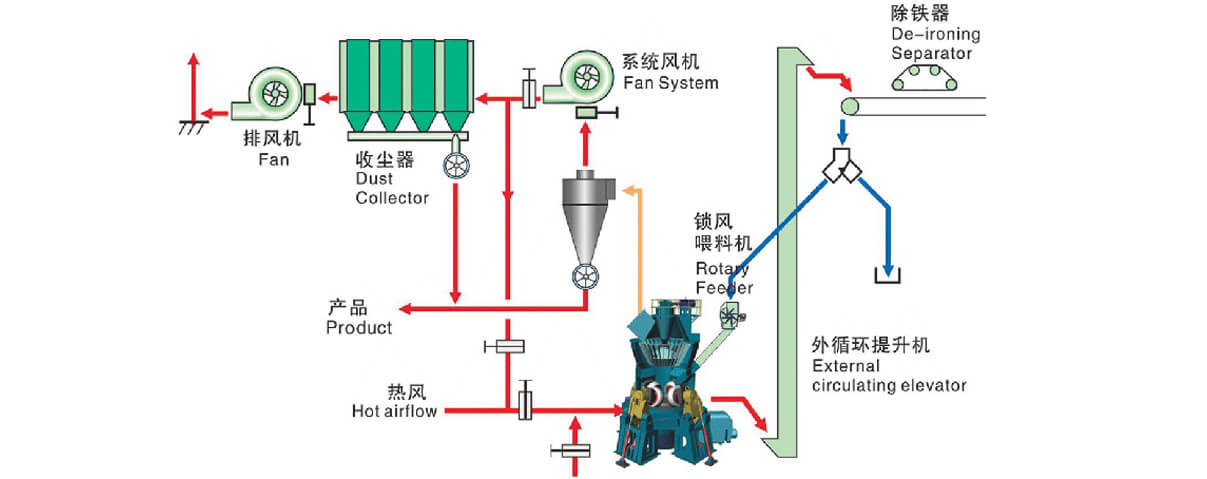

Secondary dust collection system

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Good Quality Vertical/Horizental Planetary Ball Mill Machine for Grinding Powder, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Good Quality Vertical/Horizental Planetary Ball Mill Machine for Grinding Powder, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.

Good Quality China Planetary Ball Mill and Nano Ball Mill, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Good Quality Vertical/Horizental Planetary Ball Mill Machine for Grinding Powder, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Good Quality Vertical/Horizental Planetary Ball Mill Machine for Grinding Powder, We’ve been sincerely looking forward to cooperate with shoppers all over the globe. We believe we can satisfy you. We also warmly welcome prospects to go to our company and purchase our goods.