Structure and Principle

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for HCM Customized 3000 Mesh Grinding Mill Equipment for Barite Bentonite Calcium Carbonate Gypsum Limestone Quartz Graphite Feldspar Barite Powder Production Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for China Machine and Milling Machine, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

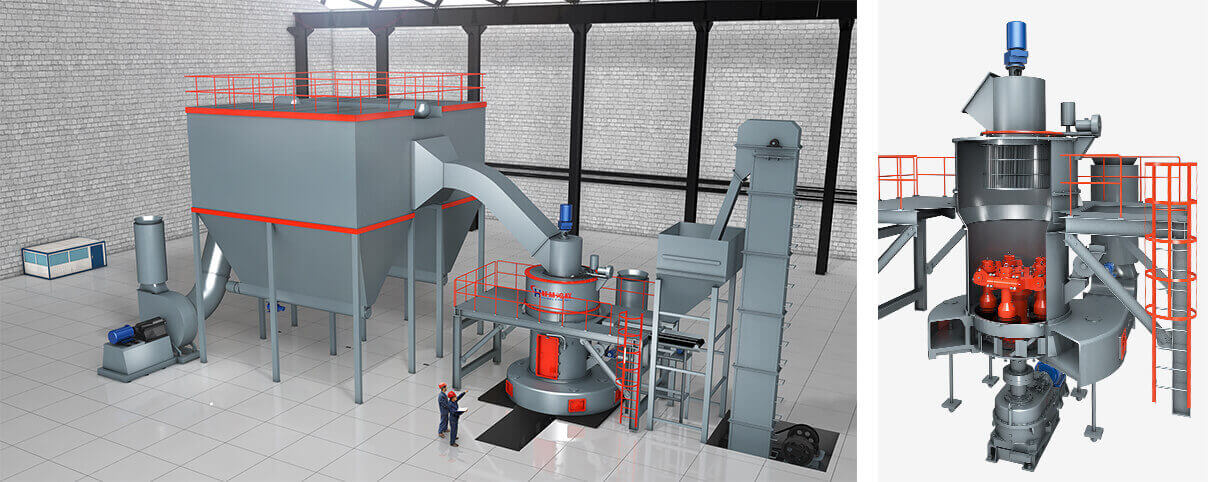

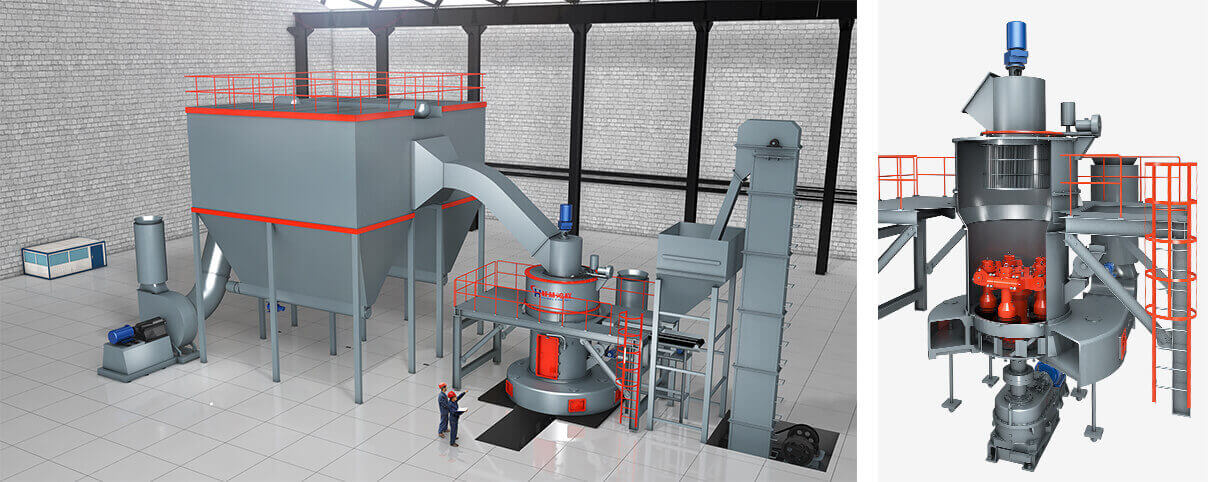

The upgraded HC super large capacity grinding mill consists of of main mill, classifier, dust collector and other components. The main mill adopts integral casting base structure, and can use cushioning base. The classifying system adopts turbine classifier structure, and the collection system adopts pulse collection.

Raw materials are delivered by forklift to the hopper and crushed by crusher to less than 40mm, and material is lifted by elevator to the storage hopper of the mill. When the material is discharged from the hopper, the feeder sends the material evenly to the main mill for grinding. The qualified powders are classified by the classifier and then enter the pulse dust collector through the pipeline. The powders are collected by the pulse dust collector and discharged through the discharge port at the bottom of the pulse dust collector and delivered to the trash bin. The system is designed as an open loop system, the dust removal is full pulse collection, which has 99.9% pulse collection efficiency. The mill throughput can be greatly increased and it will be more environmentally friendly. Since the HC super large capacity grinding mill very high throughput which can cannot be manually packaged, it needs to be transported to the powder storage tank before packaging.

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for HCM Customized 3000 Mesh Grinding Mill Equipment for Barite Bentonite Calcium Carbonate Gypsum Limestone Quartz Graphite Feldspar Barite Powder Production Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for HCM Customized 3000 Mesh Grinding Mill Equipment for Barite Bentonite Calcium Carbonate Gypsum Limestone Quartz Graphite Feldspar Barite Powder Production Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

HCM Customized China Machine and Milling Machine, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for HCM Customized 3000 Mesh Grinding Mill Equipment for Barite Bentonite Calcium Carbonate Gypsum Limestone Quartz Graphite Feldspar Barite Powder Production Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for HCM Customized 3000 Mesh Grinding Mill Equipment for Barite Bentonite Calcium Carbonate Gypsum Limestone Quartz Graphite Feldspar Barite Powder Production Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.