Cov iav pov tseg yog ib hom khib nyiab hauv tsev, nws muaj yeej tsis yog ua rau tib neeg kev tsim txom thiab muaj kuab paug rau ib puag ncig, thiab nce cov av ib puag ncig, thiab ua rau muaj thaj av muaj txiaj ntsig. Khwv yees duab suav tias yog 3.2 lab tons ntawm cov iav pov tseg txhua xyoo, suav nyiaj rau kwv yees li 2% ntawm tag nrho cov nyiaj ntawm cov dej khib nyiab. Nrog rau kev txhim kho ntawm cov kev ua kom muaj zog ntawm kev ua kom muaj zog thiab kev txhim kho tib neeg cov qauv muaj sia nyob, tag nrho cov nyiaj ntawm cov khib nyiab tau nce ntxiv. Nyob rau hauv cov nqe lus ntawm kev rov ua dua tshiab thiab kev siv cov khoom siv khib nyiab, qee lub tebchaws tsim khoom lag luam hauv Tebchaws Askiv thiab Tebchaws Asmeskas tau ua tiav cov txiaj ntsig zoo kawg li. Cov neeg European thiab Asmeskas tau siv cov iav kom tiav zoo hauv kev tsim kho cov dej num, uas yog ib txoj hauv kev zoo los haus cov pa khib nyiab loj loj. Vim tias txhua yam cov khib nyiab iav tsis tas yuav txheeb tau, tsis tas yuav tsum muaj rau xim. Piv txwv, cov iav khib nyiab yog ua tiav ua ib lub tsev kho kom zoo nkauj hauv mosaic. Raws li cov khib nyiab iav lim, cov khib nyiab iav zeb uas tsim los ntawm HCM Machinery muab cov cuab yeej zoo pab rau kev rov ua dua tshiab ntawm cov ntaub qhwv. Niaj hnub no, peb yuav qhia cov txheej txheem ntau lawm ntawm cov khoom khib nyiab iav ua dua tshiab iav mosaic.

1. Cov neeg tau txais txiaj ntsig ntawm Phosphate Pob Zeb: Tau txais txiaj ntsig ntawm phosphate pob zeb yog thawj kauj ruam ntawm kev tsis txaus siab ntawm lub pob zeb hauv xov tooj ntawm lub cev thiab tshuaj lom neeg. Cov hau kev pab cuam ntau dua suav nrog lub ntiajteb txawj nqus sib cais, kev sib cais thiab sib nqus sib cais. Kev sib cais sib cais siv cov ntom ntom ntawm cov zaub mov hauv lub ore rau kev sib cais ntawm cov zaub mov, thiab sib nqus sib txawv ntawm cov zaub mov hauv lub ore rau kev sib cais.

2. Kev sib tsoo thiab sib tsoo cov pob zeb phosphate: phosphate pob zeb tom qab kev pab cuam thiab kev sib tsoo kom zoo dua tso tawm cov zaub mov muaj txiaj ntsig zoo hauv cov oree. Kev sib tsoo feem ntau yog siv PUAB TSAIG CRUSHER, Lub khob hliav qab crusher thiab lwm yam khoom siv los tsoo cov pob zeb phosphate mus rau qhov loj me. Kev sib tsoo yog kev siv cov zeb loj thiab ua cov tshuaj phosphote hmoov tshuab kom zoo tsoo ore, kom nws ua tau raws li qhov yuav tsum tau muaj.

3. Quaeb Cov txheej txheem leaching feem ntau muaj cov kua qaub qaub, alkali leaching thiab oxidation leaching. Acid Leaching siv ib qho kev daws acidic kom yaj cov tshuaj uas tsis pom zoo, thiab cov leeg ua kom cov oxidizing kom yaj cov phosphate.

4. Naintitation thiab frictric ntawm phosphate ores: Tom qab daws teeb meem, kev daws teeb meem xav tau precipitated thiab lim kom cais cov khoom phosphate khoom. Nag lossis daus yog siv daus daus los hloov cov tshuaj phosphateent ntawm cov kev daws teeb meem los ntawm kev daws teeb meem los ntawm cov khoom lim.

5. Kom qhuav thiab sintering phosphate pob zeb: tom qab kev ua kom tiav yog lim, nws xav tau kom qhuav thiab sintered kom tau cov khoom tiav lawm. Kom qhuav yog siv cov khoom kom ziab kom yaj cov dej hauv cov av, thiab Sintering yog qhov kub thiab txias sinting, yog li ntawd nws ua rau lub suab hluav taws xob ntau.

6. Phosphate Tailings Dailings: Phosphate Ore ua cov txheej txheem yuav tsim ib qho nqi ntawm tailings, tailings muaj cov zaub mov tsis muaj zog thiab impurities. Txhawm rau kom txo cov pa phem ib puag ncig thiab pov tseg ntawm cov khoom siv, cov cuab yeej yuav tsum tau kho. Cov kev kho mob uas ib txwm muaj xws li tailings stacking, tailings ub thiab tailings kev siv.

Cov txheej txheem ntau lawm ntawm cov xauv iav Everycling thiab txoj kev melting yog feem ntau siv, thiab cov hmoov av ntau lawm ntawm cov hmoov av thiab ceramic mosis yog tib yam. Cov txheej txheem ntau lawm yog kom zoo zom cov ntaub khib nyiab cov hmoov khib nyiab kom tau raws li cov hmoov nplaum uas nplaum (inorganic lossis tus neeg sawv cev tsis sib xws, nrog tus Tov khoom los sib tov nws mus rau hauv ib qho kev sib txuas ua ke. Qhov sib tov yog nias rau hauv ntau cov duab geometric los ntawm cov qauv nias kom qhuav, thawb lub cev kiln thiab qhov kub ntawm 800-900 degrees Celsius rau Sintering. Feem ntau, nws nyob qis qis hauv thaj chaw si sintering kub rau 1.5-2.5 teev. Cov khoom txias txias tawm ntawm cov kiln rau kev tshuaj ntsuam, kev nkag, tshuaj xyuas, ntim khoom, ntim khoom siv lossis tsis tsim nyog tau rov ua tau. Cov txheej txheem melting yog raws li cov iav pov tseg (tus nqi ntawm cov neeg yog 25-60, feldspar, felula tshauv thiab emulsion tus neeg sawv cev ntawm cov khib nyiab los ntawm cov khib nyiab iav Mechanism rau cov khaub ncaws sib txuam, thiab tom qab ntawd ua kom lub siab npau npau (melting kub yog 1400-1500) kom yaj mus rau hauv cov kua iav niaj hnub. Lub khob kua ntws mus rau hauv lub calender thiab tau nias rau hauv lub khob thaiv ntawm ib qho loj me thiab cov duab, uas xa mus rau analing kiln. Cov khoom annealed tuaj yeem khaws cia lossis xa tawm tom qab kuaj xyuas, kev tso chaw thiab ntim khoom.

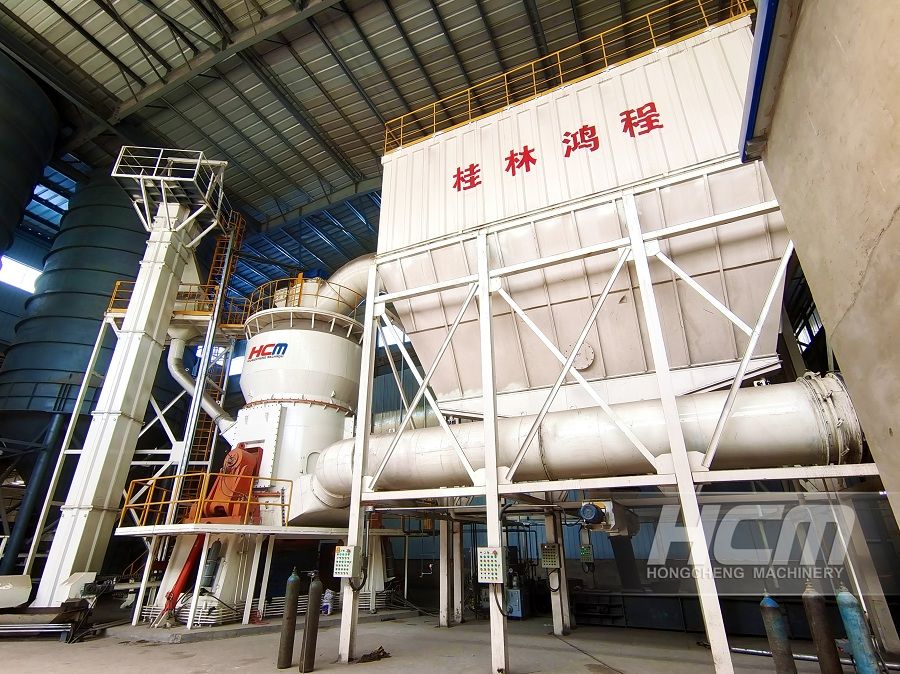

Khib Iav Recycling iav Mosaics yog raws li kev sib tsoo cov iav pov tseg rau hauv iav hmoov. Khib Iav Zeb yog cov khoom siv tsim rau kev ua cov iav hmoov. Cov iav khib nyiab uas tsim los ntawmHCM tshuab has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Lub Sijhawm Post: Jan-08-2024