At present, the wet beneficiation process is mainly used to improve the ore grade. The slurry grinding process needs to consume a lot of water resources, especially in the mine areas lacking water sources. Water conservation and water intake become difficult problems. In order to alleviate the above problems, grinding and beneficiation under the condition of no water or less water consumption has become the goal pursued by people. Therefore, the dry grinding and separation process of iron ore has great development potential. HCMilling(Guilin Hongcheng) is the manufacturer of iron ore beneficiation vertical roller mill. Hereinafter, we will introduce the dry grinding and separation process of iron ore.

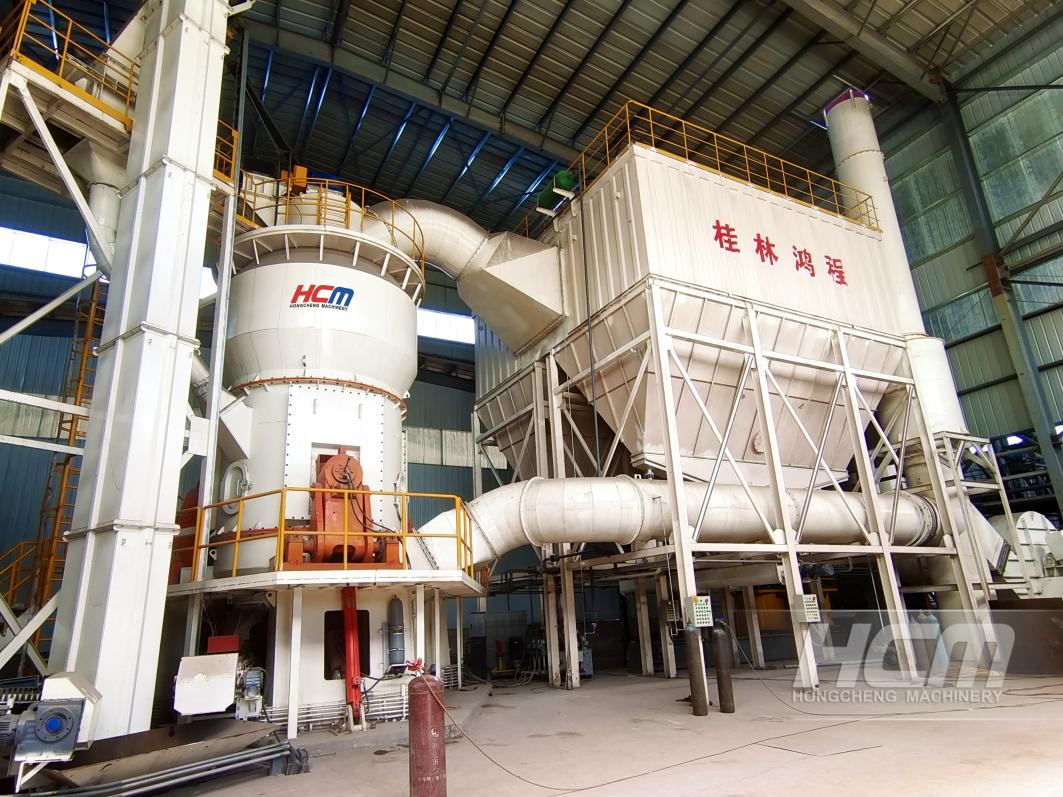

HLM iron ore beneficiation vertical roller mill

The dry grinding and separation process of iron ore includes the following equipment: iron ore beneficiation vertical roller mill, multi-stage lifting air separator and multi-stage magnetic roll concentrator. The feeding port of the iron ore beneficiation vertical roller mill is equipped with a feeding mechanism. The discharge port of the iron ore beneficiation vertical roller mill is connected with the feed port of the multi-stage lifting air separator through the particle conveying mechanism, and the powder outlet of the multi-stage lifting air separator is connected with the powder collecting device, The discharge outlet of the multistage lifting air separator is connected to the feed inlet of the multistage magnetic roller concentrator through the discharge pipe, the concentrate outlet of the multistage magnetic roller concentrator is connected to the concentrate collection device, the tailing outlet of the multistage magnetic roller concentrator is connected to the tailing collection device, and the middling outlet of the multistage magnetic roller concentrator is connected to the feed inlet of the iron ore beneficiation vertical roller mill through the return conveyor.

(a) Dry grinding: grind the crushed iron ore into a mixture of ore particles and ore powder through the vertical roller mill of iron ore dressing;

(b) Air separation and classification: the ore powder and ore particles are separated by multistage lifting air separator, and then the separated ore powder is collected by the powder collector;

(c) Dry multistage magnetic separation: the ore particles are subject to multistage magnetic separation by multistage magnetic roller concentrator to separate them into high-grade concentrate, middlings of general grade and low-grade tailings. The concentrates and tailings are collected respectively, and the middlings are returned to the dry vertical roller mill for regrinding.

HCMilling(Guilin Hongcheng) is a manufacturer of iron ore beneficiation vertical roller mill. HLM series iron ore beneficiation vertical roller mill produced by us is the main equipment of iron ore dry grinding separation process. Aiming at the problem of large water consumption in the existing wet grinding and beneficiation process, it provides a dry grinding and separation process and device for iron ore. The process method and device can be used for grinding and beneficiation without water or with less water consumption.

If you have the demand for iron ore dry grinding separation process and equipment, please contact our E-mail: mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check https://www.hc-mill.com/.

Post time: Nov-12-2022