As an important mineral resource, dolomite plays an important role in all walks of life due to its unique physical and chemical properties and wide application value. This article will introduce in detail the resource situation of dolomite, the downstream application of 300 mesh dolomite powder, and the relevant content of 300 mesh dolomite powder production line , especially its process characteristics and advantages.

Introduction and resources of dolomite

Dolomite is a rock mainly composed of dolomite, with complete cleavage of three groups of rhombohedrons, brittleness, Mohs hardness between 3.5-4 , and specific gravity of 2.8-2.9 . This rock reacts slowly in cold dilute hydrochloric acid, showing its unique chemical properties. Dolomite resources are found in all provinces and regions of China, but most mines are small in scale, with a short mining period, relatively low technical means, and relatively small investment scale of mines. Despite this, the abundant reserves of dolomite still provide a solid foundation for its wide application in various industrial applications.

Downstream applications of 300 mesh dolomite

300 mesh dolomite powder refers to dolomite that has been processed to a fine powder with a particle size of 300 mesh. Dolomite powder of this fineness has a wide range of applications in many fields. For example, it can be used as a filler in plastic, rubber, paint, and waterproof material factories to make various high-performance materials; in the glass industry, dolomite powder can significantly reduce the high-temperature viscosity of glass and improve the chemical stability and mechanical strength of the products. Among them, 300 mesh dolomite powder is widely used in putty powder and is the main inorganic raw material for putty powder.

300 mesh dolomite powder production line

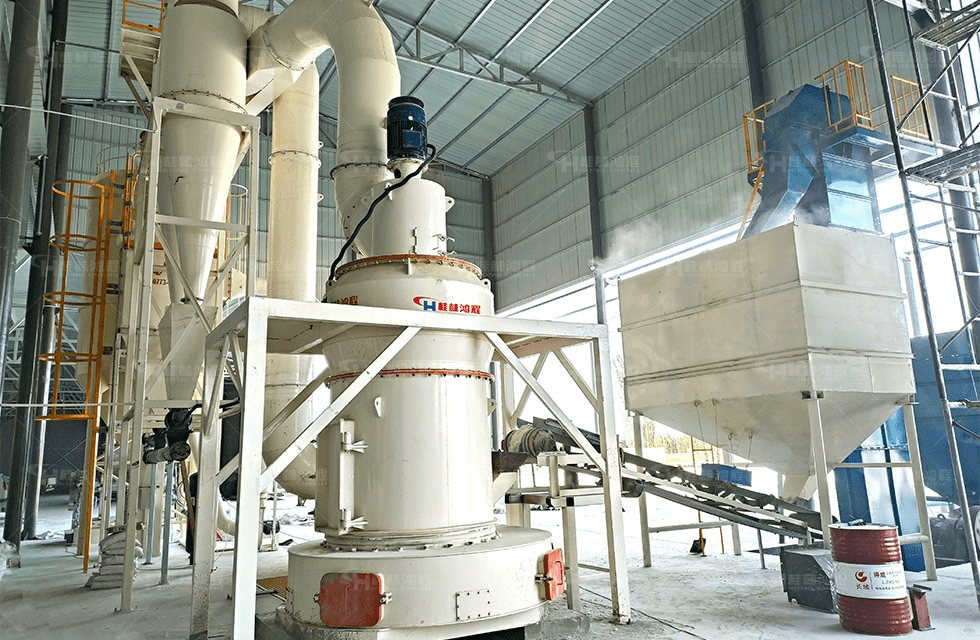

300 mesh dolomite powder production line is very important, which is directly related to the quality and production efficiency of the product. An efficient and intelligent 300 mesh dolomite powder production line of grinding mill expert Guilin Hongcheng usually includes:

1. Crushing equipment: Large pieces of dolomite are first crushed once, twice or even multiple times by a crusher to ensure the high efficiency of subsequent grinding. Generally, a jaw crusher is used, and it is best to crush the dolomite to a particle size of less than 3 cm.

2. Grinding equipment: After crushing, dolomite enters the grinding equipment for fine grinding. For the requirement of 300 mesh fineness, you can choose HC series pendulum mill or HLM series vertical mill. If the hourly output is within 30 tons and you prefer cost-effectiveness, it is recommended to use HC series pendulum mill. If you require higher production capacity or want to achieve a more intelligent and efficient grinding effect, it is recommended to use HLM series vertical mill.

3. Classification: The ground dolomite powder is classified by a classifier to ensure that the final product reaches the 300 mesh fineness standard. This step is the key to ensuring product quality.

4. Dust collection and packaging: Qualified 300 -mesh dolomite powder is collected in the dust collection system and sent to the finished product silo for packaging for subsequent use.

In addition, Guilin Hongcheng 300 -mesh dolomite powder production line also includes auxiliary equipment such as feeders, bucket elevators, electronic control systems, and pipeline devices. These equipment cooperate with the main equipment to form a complete and efficient production system.

Guilin Hongcheng 300 mesh dolomite powder production line meets the market demand for high-quality dolomite powder with its efficient and stable production capacity. Hongcheng has professional pre-sales technical engineers who can customize exclusive solutions for customers according to project requirements. Welcome to contact us。

Post time: Oct-29-2024