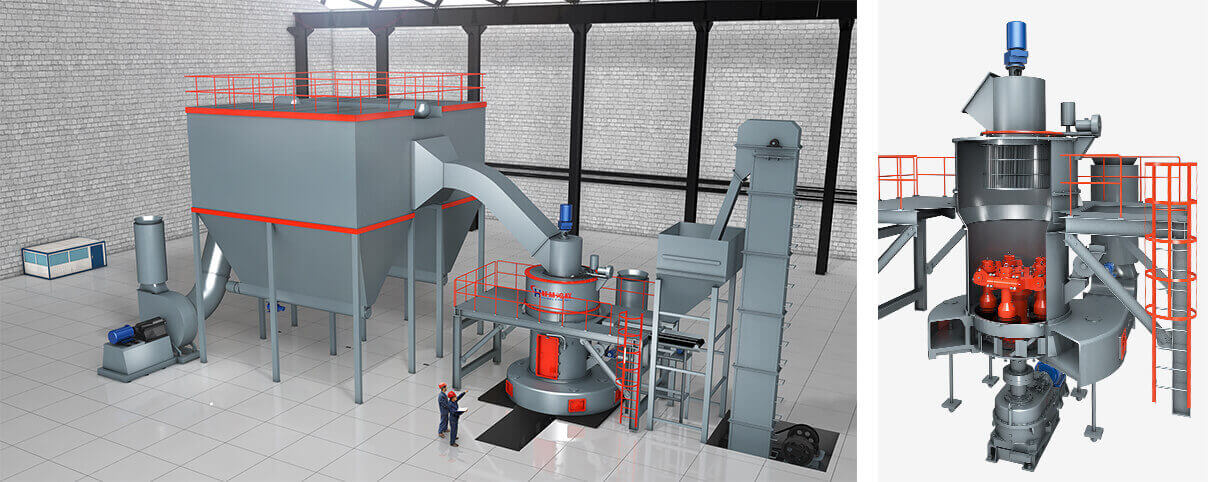

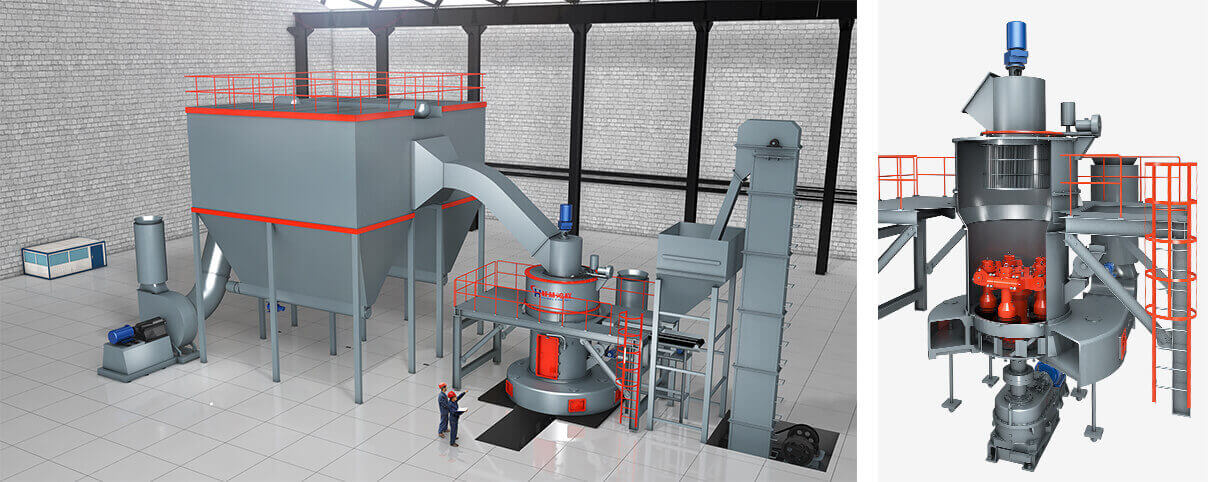

The upgraded HC super large capacity grinding mill consists of of main mill, classifier, dust collector and other components. The main mill adopts integral casting base structure, and can use cushioning base. The classifying system adopts turbine classifier structure, and the collection system adopts pulse collection.

Raw materials are delivered by forklift to the hopper and crushed by crusher to less than 40mm, and material is lifted by elevator to the storage hopper of the mill. When the material is discharged from the hopper, the feeder sends the material evenly to the main mill for grinding. The qualified powders are classified by the classifier and then enter the pulse dust collector through the pipeline. The powders are collected by the pulse dust collector and discharged through the discharge port at the bottom of the pulse dust collector and delivered to the trash bin. The system is designed as an open loop system, the dust removal is full pulse collection, which has 99.9% pulse collection efficiency. The mill throughput can be greatly increased and it will be more environmentally friendly. Since the HC super large capacity grinding mill very high throughput which can cannot be manually packaged, it needs to be transported to the powder storage tank before packaging.

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for OEM/ODM Manufacturer Raymond Grinder Part - HC Super Large Grinding Machine – HCM, The product will supply to all over the world, such as: Moldova, Lyon, Qatar, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.