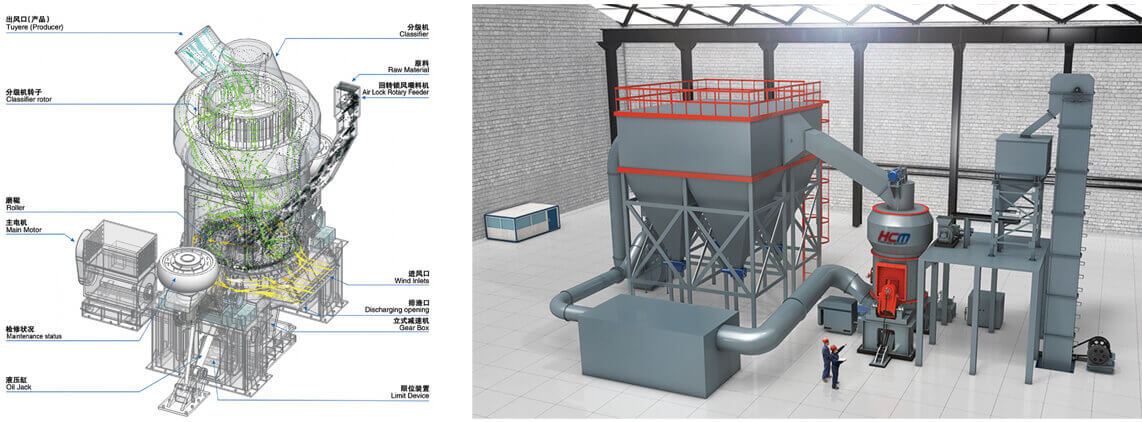

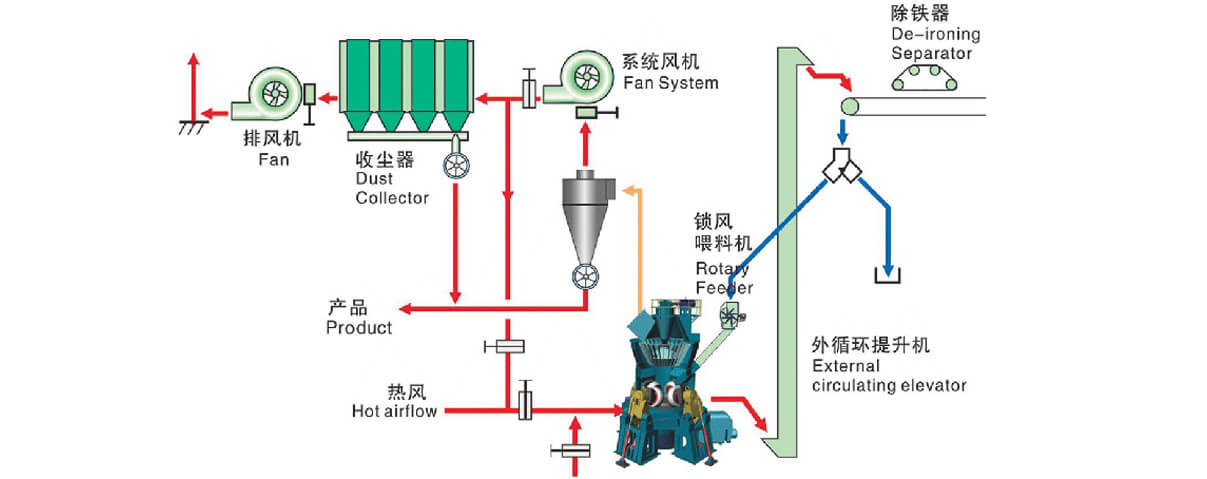

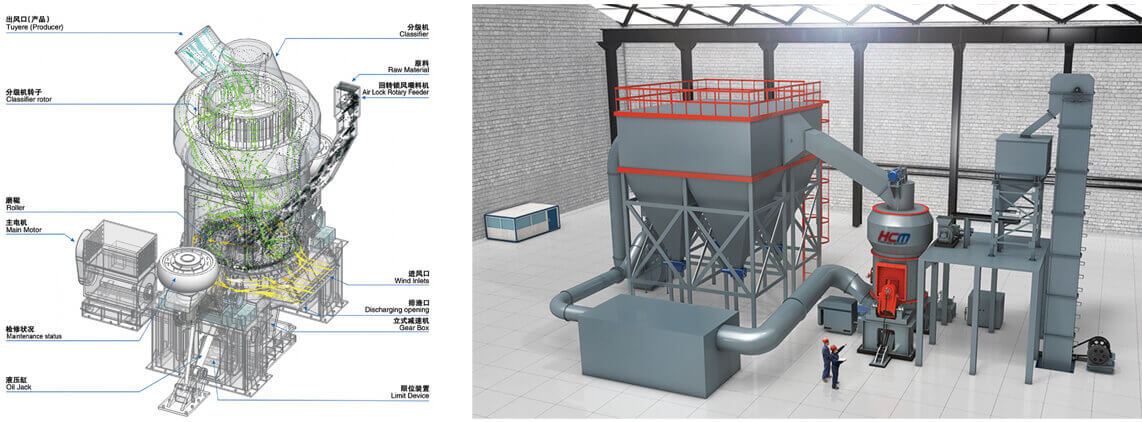

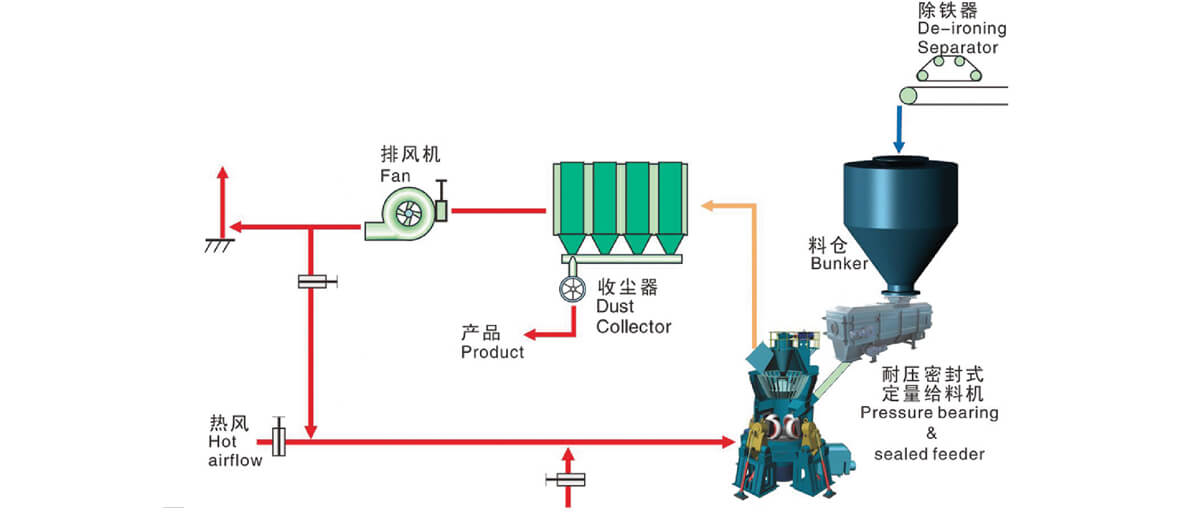

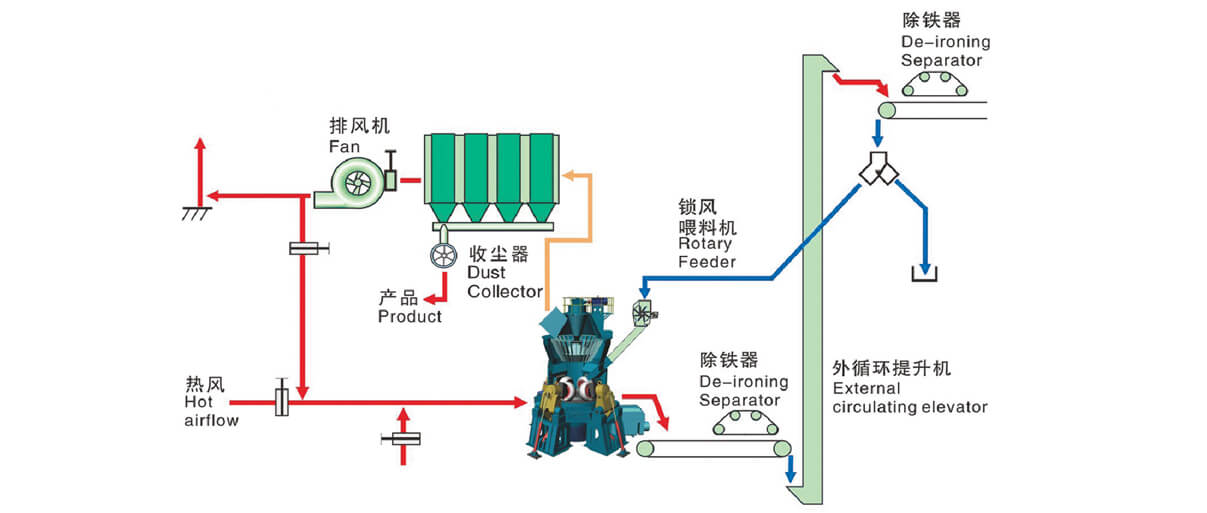

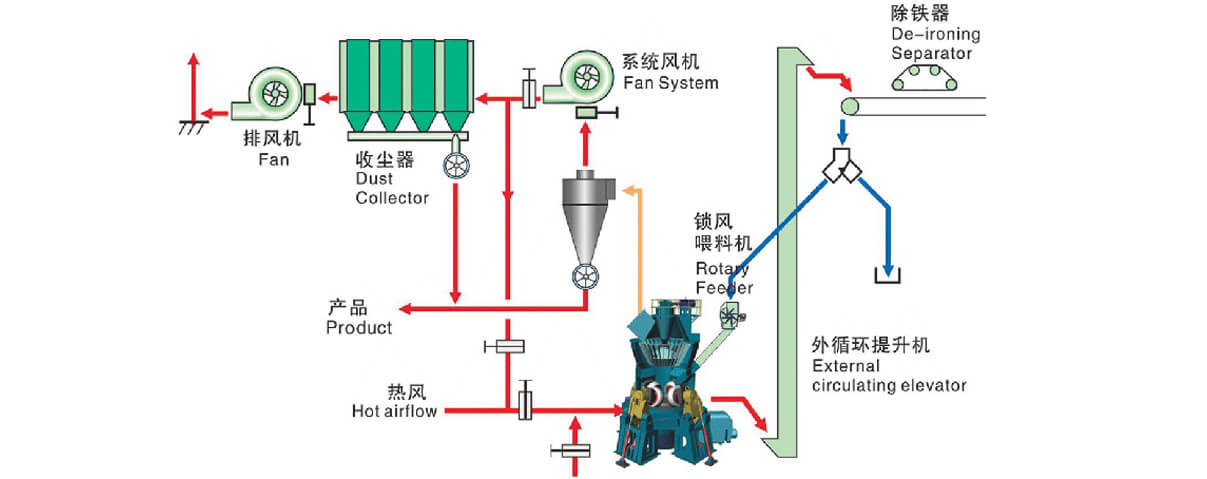

The motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and pulverized through squeezing, grinding and cutting. Simultaneously, the hot air is blew up around the dial and brow up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

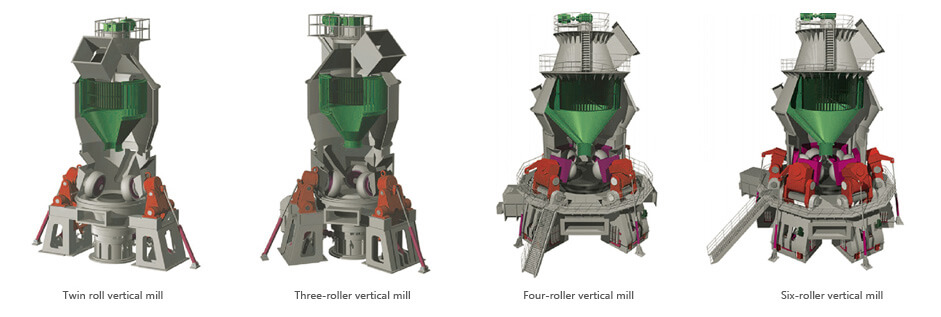

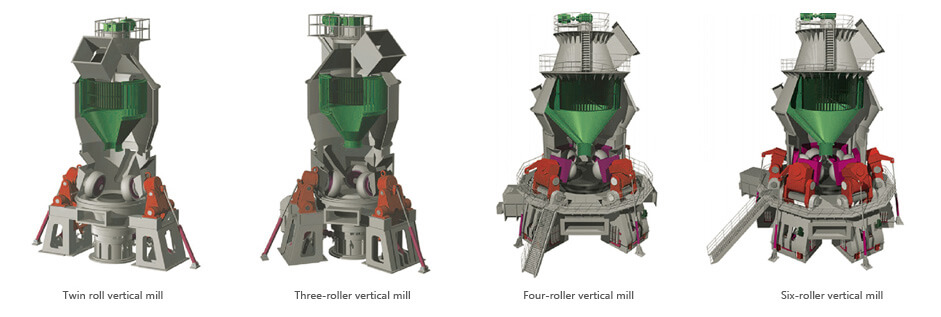

HLM vertical roller mill using standard modules to design and fabricate pressurization device. As the capacity increases, the roller numbers will increase (we can use 2, 3 or 4, maximum 6 rollers ) in proper permutation and combination to set different series of equipment with different capacities by minimum standard parts to meet the requirements of different materials, fineness and outputs.

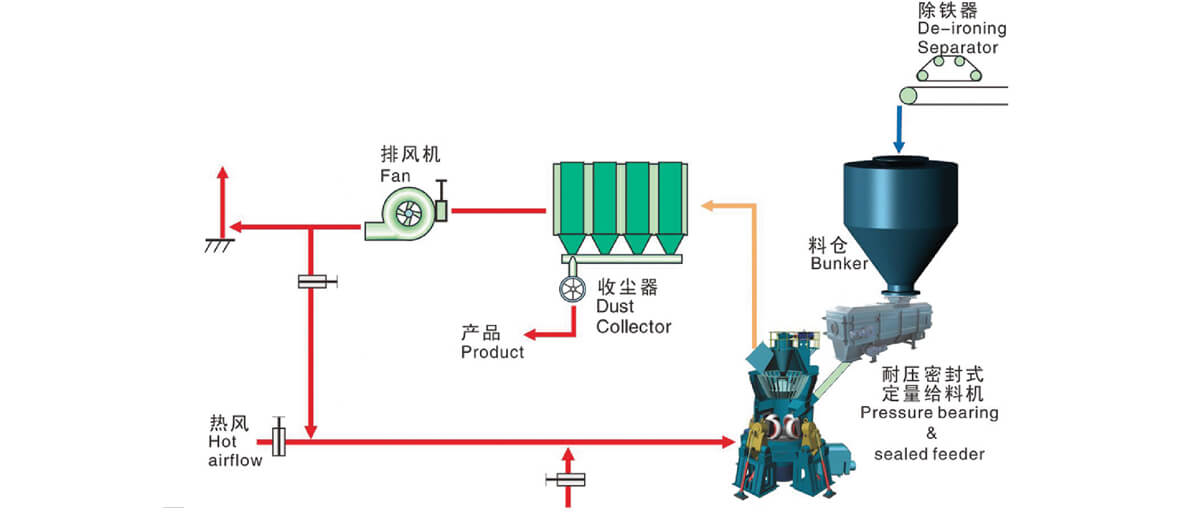

Unique Dust Collection System I

Single dust collection system II

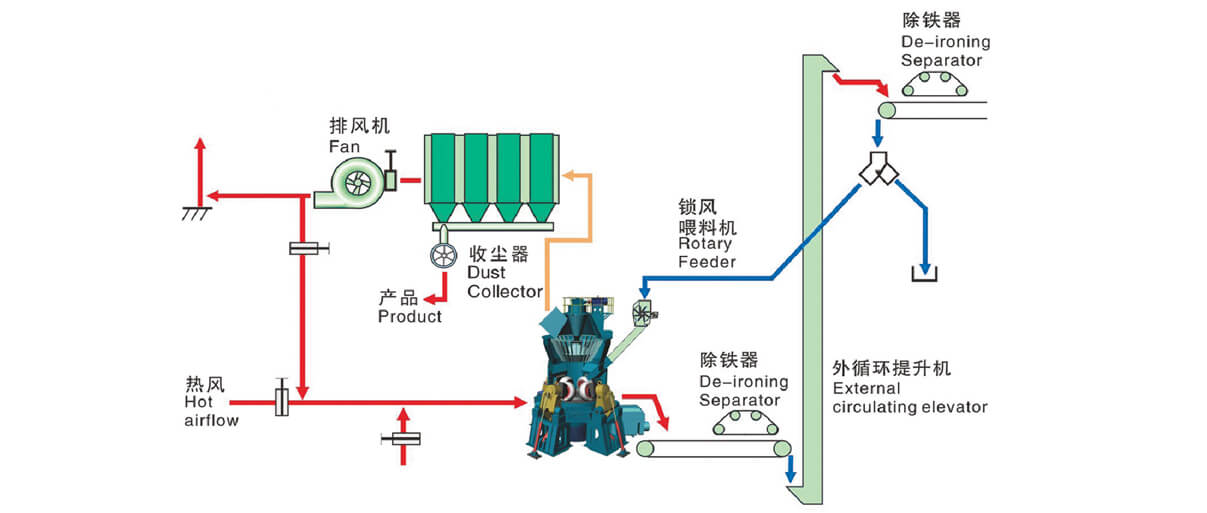

Secondary dust collection system

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Rapid Delivery for Cement Vertical Mill Picture Gallery - HLM Vertical Roller Mill – HCM, The product will supply to all over the world, such as: United Arab Emirates, Los Angeles, Costa Rica, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.