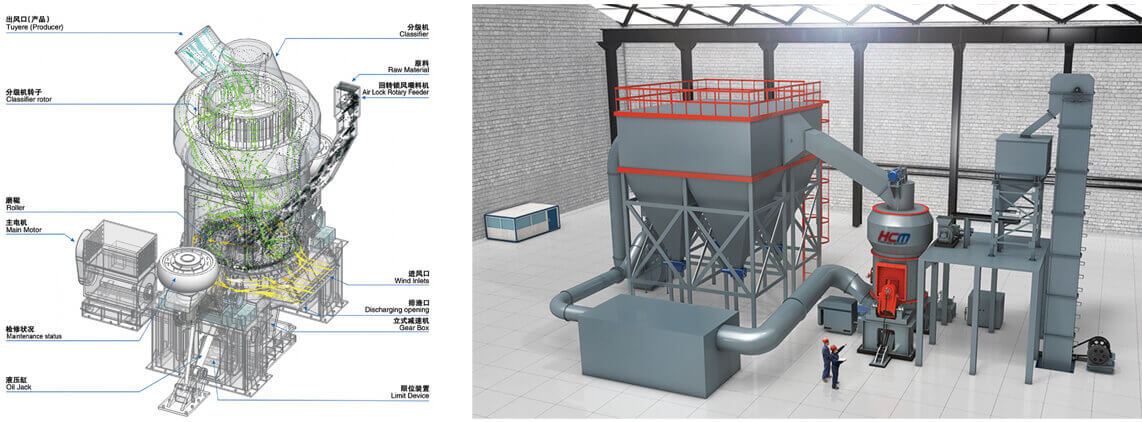

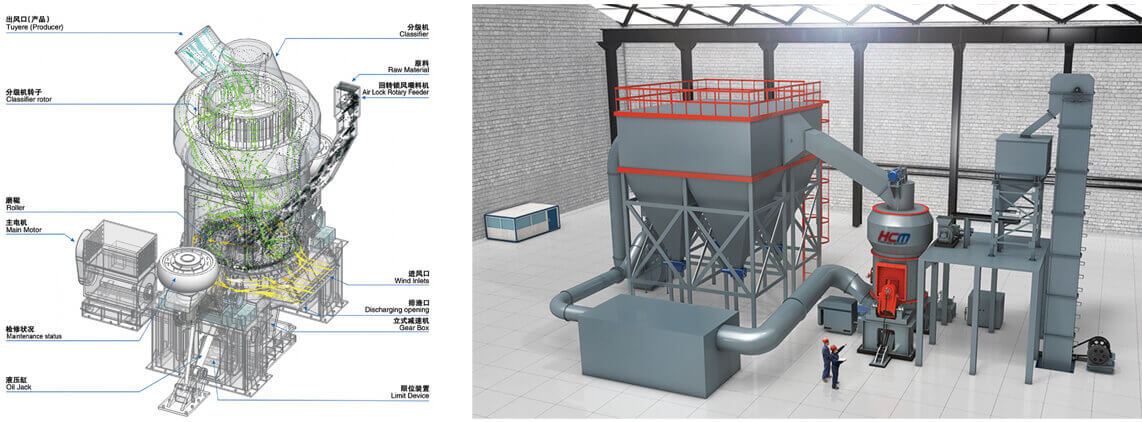

Structure and Principle

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Reliable Supplier Mining Machine High Chrome Casting Wear-Resisting Roller for Super Fine Mill, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”.

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for China Roller and Mill Roller, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to to suit your needs of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’re confident that we’re going to have a bright prospect and to be distributed all over the world in the years to come.

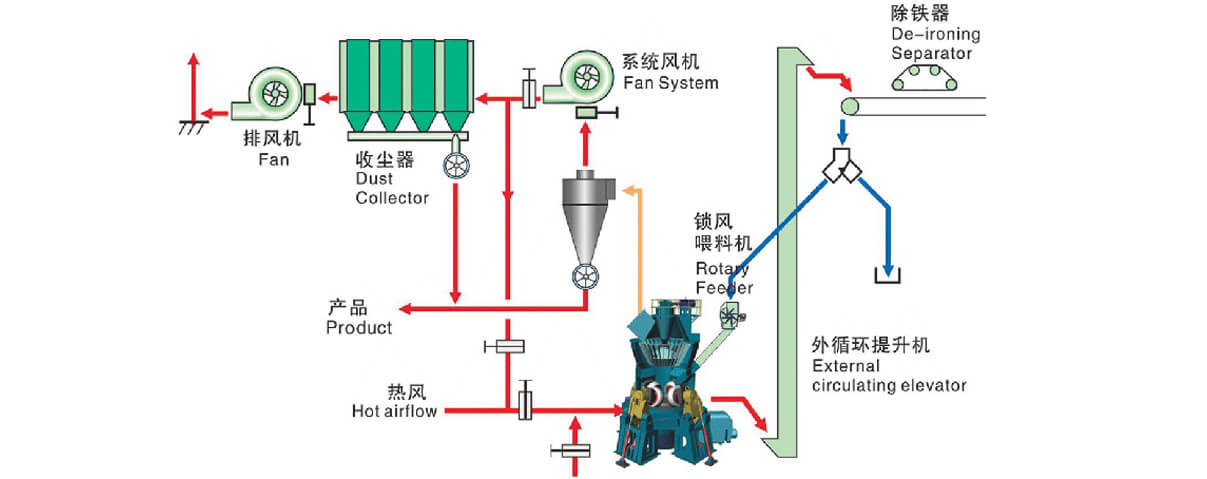

As the vertical roller mill works, the motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and pulverized through squeezing, grinding and cutting. Simultaneously, the hot air is blew up around the dial and brow up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

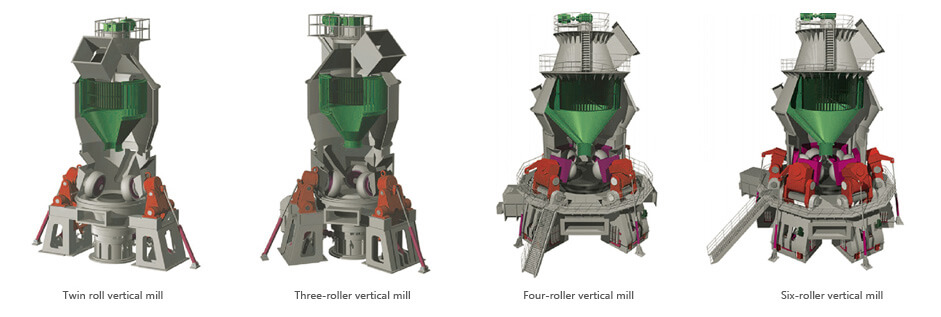

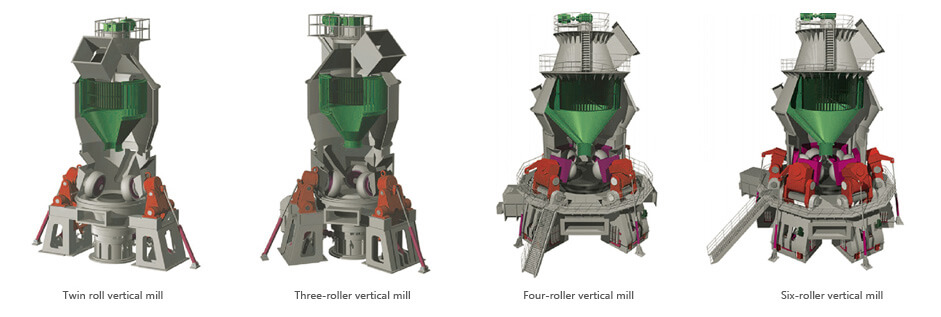

HLM vertical roller mill using standard modules to design and fabricate pressurization device. As the capacity increases, the roller numbers will increase (we can use 2, 3 or 4, maximum 6 rollers ) in proper permutation and combination to set different series of equipment with different capacities by minimum standard parts to meet the requirements of different materials, fineness and outputs.

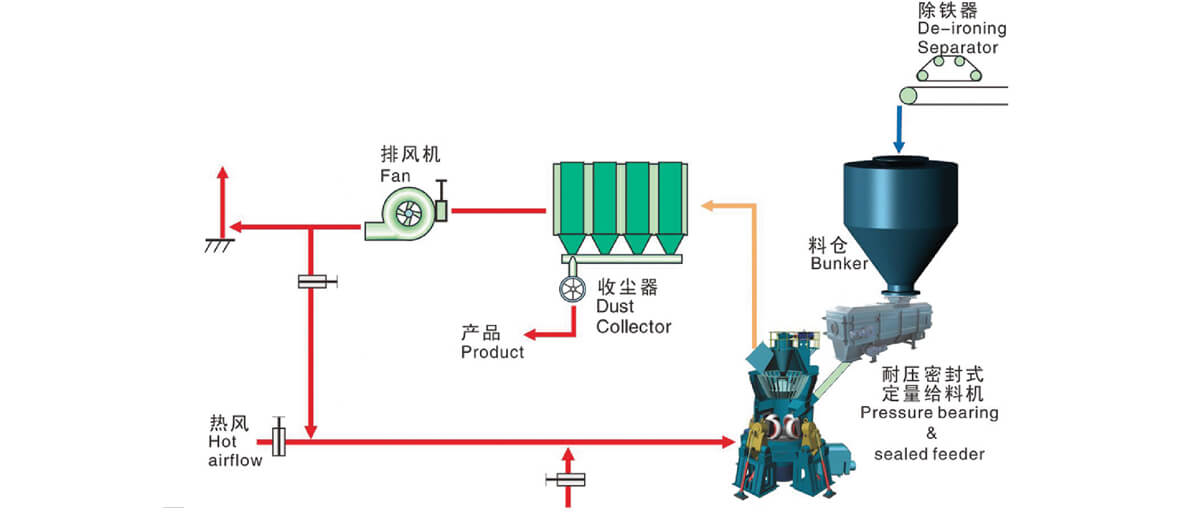

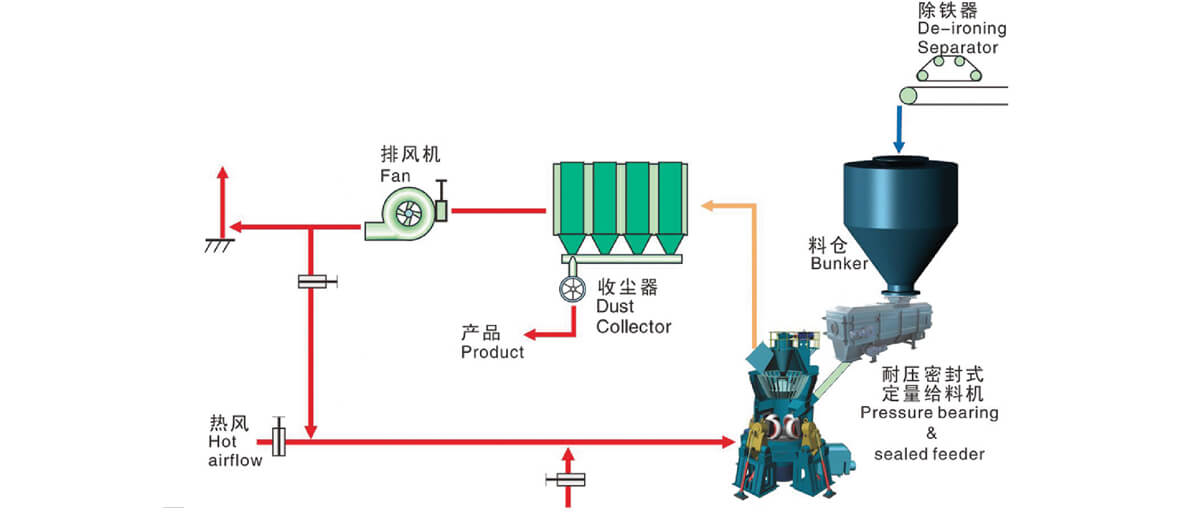

Unique Dust Collection System I

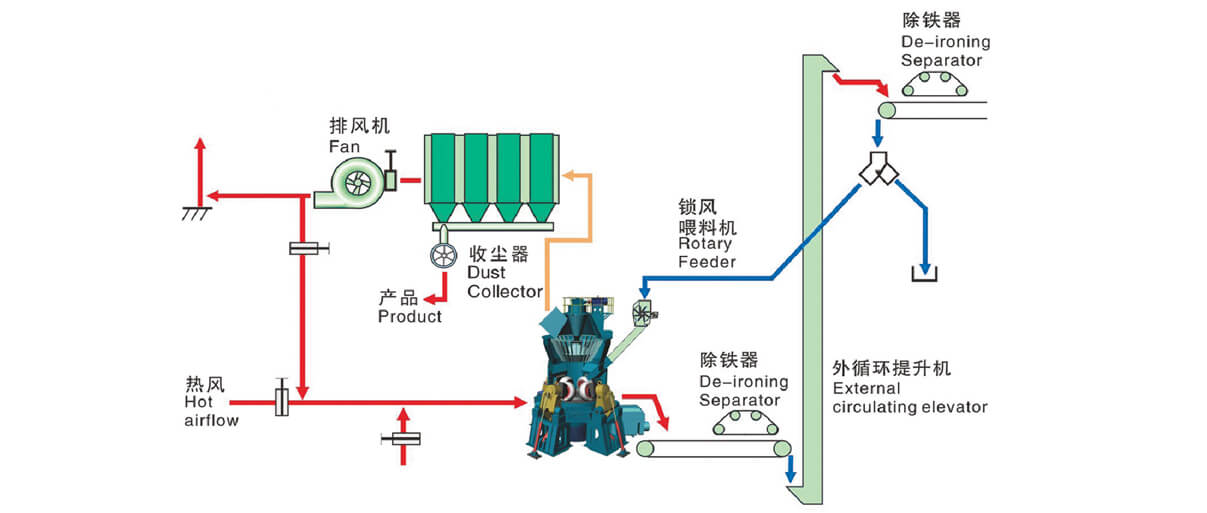

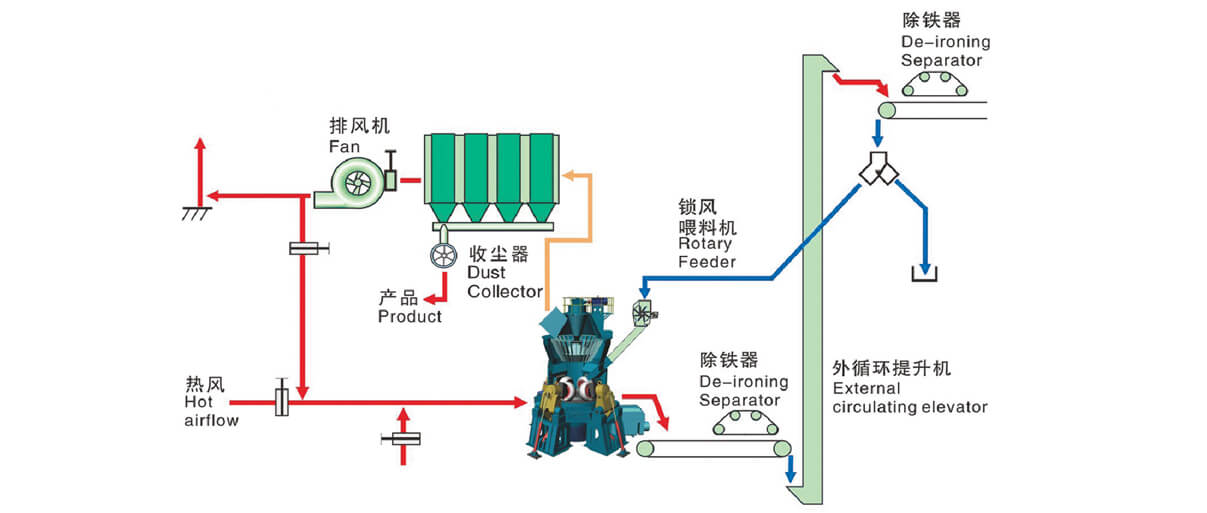

Single dust collection system II

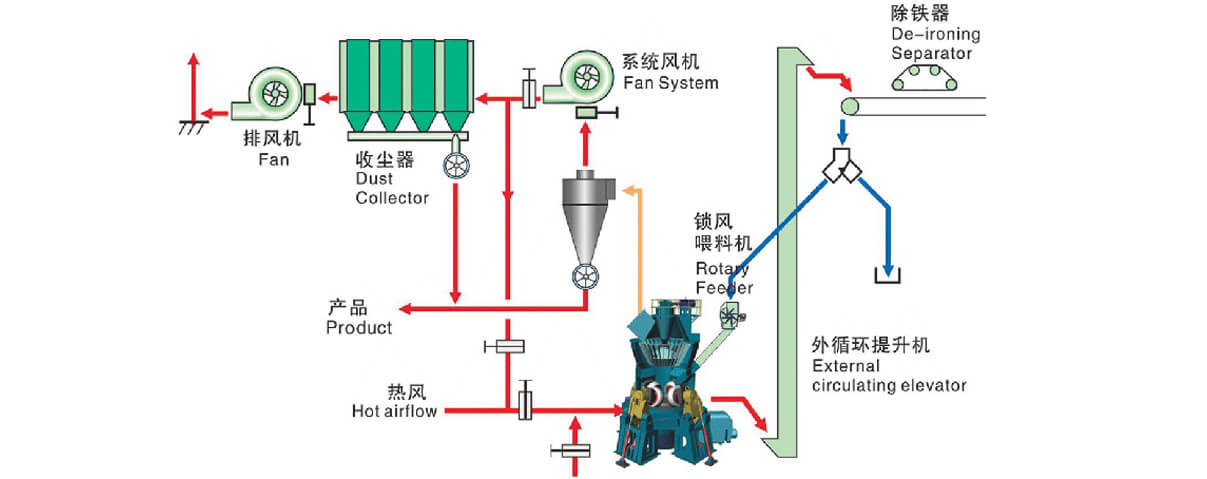

Secondary dust collection system

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Reliable Supplier Mining Machine High Chrome Casting Wear-Resisting Roller for Super Fine Mill, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”.

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Reliable Supplier Mining Machine High Chrome Casting Wear-Resisting Roller for Super Fine Mill, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”.

Reliable Supplier China Roller and Mill Roller, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to to suit your needs of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’re confident that we’re going to have a bright prospect and to be distributed all over the world in the years to come.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Reliable Supplier Mining Machine High Chrome Casting Wear-Resisting Roller for Super Fine Mill, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”.

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Reliable Supplier Mining Machine High Chrome Casting Wear-Resisting Roller for Super Fine Mill, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”.