Introduction to marble

Marble and Marble are all normal non-metallic materials, can be process into different fineness of powder which called as heavy calcium carbonate after grinded by grinding mill or other mine equipment, can be widely used in papermaking, plastic, rubber, household chemicals, cosmetics, building materials, paints, pharmaceuticals, food and other industries. Marble is divided into coarse concentrate and fine-grained ore, the same tone of biased plainer phase, plenty of reserves in domestic, market usage amount is relatively large, the amount of calcium content is about 96% -98%.

Application of Marble

Marble is soft, beautiful, solemn and elegant. It is mainly used for processing into various shapes and plates for building walls, floors, platforms and columns. It is also often used in memorial buildings, such as monuments, towers, statues and other materials. It is an ideal material for decorating luxury buildings. It can also be carved into practical works of art such as arts and crafts, stationery, lamps, utensils and so on. It is the traditional material of art carving. In addition, the crushed stone and corner surplus materials produced in the process of marble mining and processing are also commonly used in the production of artificial stone, terrazzo, stone rice and stone powder. It can be used as filler in coatings, plastics, rubber and other industries.

Marble Grinding process

Component analysis of marble raw materials

|

CaCO3 |

MeCO3、 CaO、MnO、SiO2 and so on |

|

50% |

50% |

Marble powder making machine model selection program

|

Specification (mesh) |

Fine powder processing(20 mesh-400 mesh) |

Deep processing of ultrafine powder(600 mesh-2000 mesh) |

|

Equipment selection program |

Vertical grinding mill or pendulum grinding mill |

Ultrafine grinding roller mill or ultrafine vertical mill |

*Note: select the main machine according to the output and fineness requirements

Analysis on grinding mill models

1.Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for marble powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2.HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3.HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4.HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Stage I: Crushing of raw materials

Large marble materials are crushed by the crusher to the feeding fineness (15mm-50mm) that can enter the pulverizer.

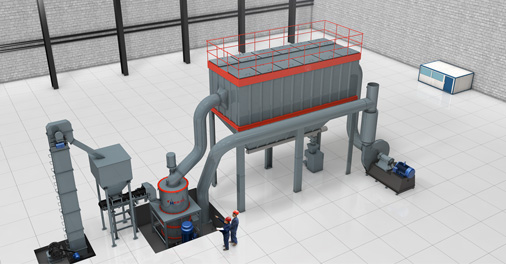

Stage II: Grinding

The crushed small marble materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Application examples of marble powder processing

Processing material: Marble

Fineness: 800 mesh D97

Capacity: 6-8t / h

Equipment configuration: 2 sets of HCH1395

Facts have proved that Hongcheng marble mill has high yield and efficiency and advanced milling technology. Choosing Hongcheng is a very correct choice. The mill not only has stable performance and stable operation, but also has high efficiency, reliable safety performance, environmental protection and energy saving, and excellent finished product quality. Since Hongcheng marble mill was officially put into the processing production line, our milling efficiency has been greatly improved, the product market feedback is good, and the reputation has been greatly improved. We are very satisfied with this reliable product quality and considerate service.

Post time: Oct-22-2021