Sefuba sa litšila ke mofuta oa litšila tsa lapeng, ho ba teng ha teng ho bakang kotsi le bophelo ba lona, empa li tlisa tšitiso ea batho feela, li nka mojaro oa tikoloho o le bohlokoa. Ho hakanngoa hore China e hlahisa lithane tse ka bang limilione tse 3.2 tsa khalase ea litšila selemo se seng le se seng, e ikarabellang bakeng sa letšoao le tiileng la lipono tse tiileng. Ka ntlafatso ea matla a phethahetseng a naha le ntlafatso ea litekanyetso tsa batho, ka khalase ea litšila e boetse e eketsehile. Mabapi le ho sebelisa khalase ea litšila, linaha tse ling tsa United Kingdom le United States li finyeletse ka mokhoa o tsotehang. Linaha tsa Europe le Amerika li atlehile ho sebelisa khalase ea litšila mererong ea kaho, e leng tsela e sebetsang ea ho ja ka khalase e ngata ea litšila. Hobane mefuta eohle ea khalase ea litšila ha e hloke ho hlophisoa, ha ho na tlhokahalo ea 'mala. Mohlala, khalase ea litšila e sebetsoa e le thepa ea mokha oa moaho ka mosa. Joaloka moetsi oa litlolo ea litšila oa litšila, leloala la litlolo tse litšila tse hlahisoang ke lisebelisoa tsa HCM li fana ka lisebelisoa tse ntle tse thusang bakeng sa ho nchafatsa khalase ea litšila. Kajeno, re tla kenyelletsa mokhoa oa tlhahiso oa khalase ea litšila hape oa khalase ea khalase ea khalase ea khalase.

1. Ho etsa puseletso lefikeng: Ho etsa sethaleng sa fpatate ke mohato oa pele ts'ebetsong ea lefika la phosphate le susumetsang ka metsamao ea phosphate ka mekhoa ea 'mele le ea lik'kene. Mekhoa e tloaelehileng ea ho etsa khaolo e kenyelletsa karohano ea matla a khoheli, ho pharalla le karohano ea makenete. Borasi ba matla ba khoheli bo sebelisa phapang ea liminerale ka hare libakeng tsa liminerale tse sebelisang phapang ea likarolo tsa karohano.

2. Ho sithabela ha setšoantšo sa phosphate: Le lefika lefika ka morao, re hloka ho qhekelloa le ho tsoma kalafo e sebetsang mosebetsing. Ho sithabela hangata ho sebelisoa mohlahare oa teronko, cone Crusher le lisebelisoa tse ling ho roba lefika sethaleng sa sethala. Ho seripa ke tšebeliso ea tlhahiso e kholo ea tlhahiso le ho sebetsana le mochini oa Popphate Pop.

3. Lefika la phosphate ke mohato oa bohlokoa ts'ebetsong ea lefika la phosphate, ka har'a metsoako efe e bohlokoa joalo ka phosfote e ka qhibiliha ho ore. Mekhoa e tloaelehileng ea lecheng e tloaelehileng e kenyelletsa lechi ea Acid, Leqhubu la Alkali le Leoatle la oxidation. Acid leches e sebelisa tharollo ea acid, Alkaline e sebelisa tharollo ea alfaline ho qhibiliha sekhechana sa phosphate.

4. Ho thetsoa ha Prapphate ores: Kamora ho ipeha ka mor'a ho leleke, tharollo ea likarolo tse nang le phosphate e hlokang ho qhekelloa ebile e hloekisoa ho arola lihlahisoa tse tiileng tsa phosphate. Pula ke tšebeliso ea moemeli ea ntseng a le teng ho fetola karolo eo bakeng sa tharollo e tiileng, 'me ho hatisoa ke ho arola lisebelisoa tsa motlakase ka har'a lisebelisoa tsa sefa.

5. Ho omella le ho silaka lefika la phosphate: Ho omella ke ts'ebeliso ea lisebelisoa tsa ho omisa ho bolaea metsi ka seriti, 'me ho silafaloa ke ntho ea mocheso e phahameng.

6 Ex. Bakeng sa ho fokotsa tšilafalo ea tikoloho le litšila tsa lisebelisoa, mesifa e hloka ho tšoaroa. Mekhoa e tloaelehileng ea ho futhumatsa meaho e kenyelletsa liqhomane tsa methapo ea liqhomane, li otla ho khutlisa le ho taka ts'ebeliso e felletseng.

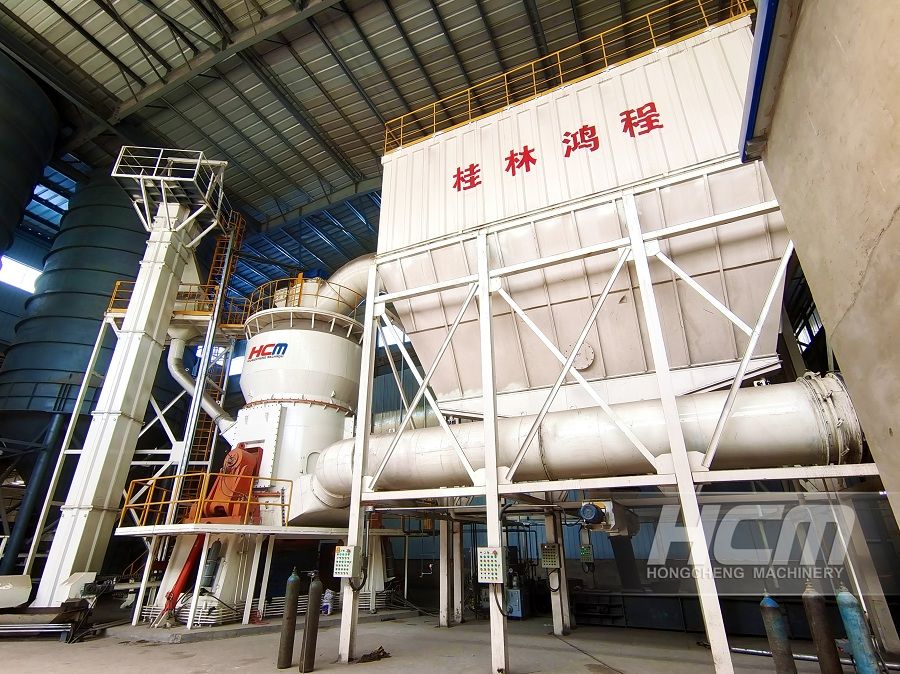

Tsamaiso ea tlhahiso ea khalase ea litšila e nchafatsa khalase ea khalase ea khalase ea khalase: Mokhoa oa ho qhibiliha le mekhoa ea ho qhibiliha ka mokhoa oa ho etsa motsotsi oa mekhoa ea sim ea ceramic e joalo. Ts'ebetso ea taolo ea sehlooho ke ho grind khalase ea litšila ka leloala la litšila motsoako oa ho e kopanya ka har'a company cound. Motsoako ona o hatelloa ka libopeho tse fapaneng tsa geometri ka mokhoa o omisitsoeng oa ho tobetsa o omileng, 'me setopo se omisitsoeng se romeloa ho Roller Kiln, Just Celn Ka kakaretso, e lula sebakeng sa mocheso o mobe bakeng sa lihora tse 1.5-2.5. Lihlahisoa tse futhumatsang kantle ho kiln bakeng sa tlhahlobo, ho beoa, ho omella, ho lekola, ho boloka lihlahisoa, lihlahisoa tse sa bonahaleng li sebelisoa hape. Mokhoa oa ho qhibiliha o ipapisitse le khalase ea litšila (palo ea batho ke lehlabathe le tala, lash le moemeli oa lisepa Mechanism ka phofo e tšoanang le ea chefo, ebe ka mocheso o phahameng oa ho qhibiliha mohloa o mongata (mocheso o 14,00-1500) ho qhibiliha mokelikeli oa khalase ea junifomo. Mokokotlo oa khalase o phalla ka caleander 'me o hatelloa ka har'a khalase ea boholo bo itseng le sebopeho se rometsoeng sethaleng sa kiln. Lihlahisoa tse neng li ngolisoa tse tsamaisitsoeng li ka bolokoa kapa tsa tsamaisoa kamora tlhahlobo, ho beoa le ho sephutheloana.

Lits'enyehelo tsa Ts'ireletso ea Litšoele Tse Ho Theha Lits'oaetso tsa Baeti tsa Lisacling li ipapisitse le ho silafatsa khalase ea ho chechisa khalase. Li-beare tsa beali tsa litšila ke lisebelisoa tsa tlhahiso bakeng sa ho sebetsa phofo ea khalase. Leloala la litlolo tsa litšila tse hlahisitsoeng keMechini ea HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nako ea poso: Jan-08-2024