Kenyelletso ea mashala

Mashala ke mofuta oa liminerale tsa 'mala oa cebonod. E hlophisitsoe ke khabone, monko o mong le oksijene, naetrojene le likarolo tse ling, tse ngata tse sebelisoang e le mafura a motho. Hajoale, mashala a 63 a bophahamo ba ho hlapaola ho feta peterole. Mashala a ne a bitsoa khauta e ntšo le lijo tsa indasteri, ke matla a maholo ho tloha lekholong la bo18 la lilemo. Phetohelo ea indasteri, hammoho le boqapi le ts'ebetso ea enjine ea Steam, mashala a sebelisoa haholo joalo ka mafura a maholo a indasteri bakeng sa Mokhatlo.

Kopo ea mashala

Mashala a China a arotsoe ka mekhahlelo e leshome. Ka kakaretso, mashala a letlalo, a betla mashala a mashala, mashala a mafura a mangata, mashala a khanyang le a nako e telele a kopaneng a bitsoa mashala. Lean Coal e bitsoa Sema Anthracite; Haeba litaba tse sa utloahaleng li kholo ho feta 40%, e bitsoa e metle.

Lethathamo la Claal Classifition (haholo-holo koae

| Sehlopha | Mashala a bonolo | Mashala mashala | Lean Coal | Coal Coal | Mashala a mafura | Mashala a khase | Coal e fokolang ea tlala | Mashala a sa khaotseng | Lerata le lelelele la Flame | Sootho mashala |

| Votility | 0 ~ 10 | > 10 ~ 20 | > 14 ~ 20 | 14 ~ 30 | 26 ~ 37 | > 30 | > 20 ~ 37 | > 20 ~ 37 | > 37 | > 40 |

| Litšobotsi tsa Cinder | / | 0 (phofo) | 0 (blocks) 8 ~ 20 | 12 ~ 25 | 12 ~ 25 | 9 ~ 25 | 0 (blocks) ~ 9 | 0 (phofo) | 0 ~ 5 | / |

E sephatlalatsi:

Boholo bo sootho, bo sootho bo sootho bo sootho, bo lefifi, botoro. E na le taba ea 40% taba e sa fetoheng, ntlha e tlase ea khumama ebile ho bonolo ho e fumana mollo. Ka kakaretso e sebelisoa ka khase, indasteri ea likheo tsa likheo, boiler ba matla, jj.

Mashala a lerata:

Ka kakaretso e ba granular, e nyane ebile e phofshoane, haholo-holo e ntšo le e benyang, e nang le taba e ntle, ntlha e tlase ea khumama ebile e bonolo ho e khothatsa; Mashala a mangata a mangata a hloma ebile a bonolo ho ba joalo nakong ea mollo. E sebelisoa ho choke, ho kopanya maskala, boiketsetso bo matla le indasteri ea khafatso.

Anthracite:

Ho na le mefuta e 'meli ea phofo le likotoana tse nyane, tse sootho, tse benyang ebile li be bobebe. Litšila tse fokolang, sebopeho se kopaneng, setereke se phahameng sa carbon, ho fihla ho feta 80%; Likahare tse sa utloahaleng li tlase, ka tlase ho 10%, ntlha ea Isinition e phahame, 'me ha ho bonolo ho tšoasa mollo. Palo e lekanang ea mashala le mobu o tla kenyelletsoa bakeng sa khoeli ho fokotsa matla a mollo. E ka sebelisoa ho etsa khase kapa ka kotloloho e le mafura.

Ts'ebetso phallo ea pulfarization ea mashala

Hobane ho thetsoa maskhooa, ho ipapisitse le ho imahanya le khokhopo ea eona ea ho khoptjoa ha eona. The Glondright Clught ea Koloi ea Harzburg, ho molemo le ho feta (≥ 65), le tse nyane tsa khokhopollo ea Harz, ho thata ho seriti (55-60).

LITLHAKISO:

① Khetha Mochine o ka sehloohong ho ea ka tlhahiso le litlhokahalo tsa botle;

Ts'ebeliso ea mantlha: mashala a qubung

Tlhahlobo ea mefuta ea li-mill tsa mill

1. Pendulum Mill (HC, hcq etorestori e lohiloeng):

Litšenyehelo tse tlase tsa matsete, tlhahiso e phahameng, tšebeliso e tlase ea matla, lisebelisoa tse tsitsitseng le lerata le tlase; Tharollo ke hore ts'ebeliso ea ts'ebetso le tlhokomelo e phahame ho feta ea leloala la milione.

Tafole ea bophahamo ba HC Equinding Girnding Mill (200 Mesh D90)

|

| Hc1300 | Hc1700 | Hc2000 |

| Bokhoni (T / h) | 3-5 | 8-12 | 15-20 |

| (Kw) | 90 | 160 | 315 |

| Morupeli (kw) | 90 | 160 | 315 |

| Classifier motor (kw) | 15 | 22 | 75 |

Lipuisano (tlhophiso e ka sehloohong):

Sistimi e bulehileng e bulehileng ea potoloho e nkuoa e le mashala a mabone le lesela le lelelele le nang le malinyane a phahameng.

② Plum Blossom e nang le sebopeho se nang le sebopeho se otlolohileng sa pendulum o abela sebopeho sa sleep, se nang le phello e ntle.

Sesebelisoa sa bopaki sa ③ Phatlalatsa se etselitsoe sistimi.

④ Colorctor le Pipeline e tla etsoa ho qoba ho bokellana ka lerōleng ho ea kamoo ho ka khonehang.

⑤ Bakeng sa tsamaiso ea phofo e fetisang

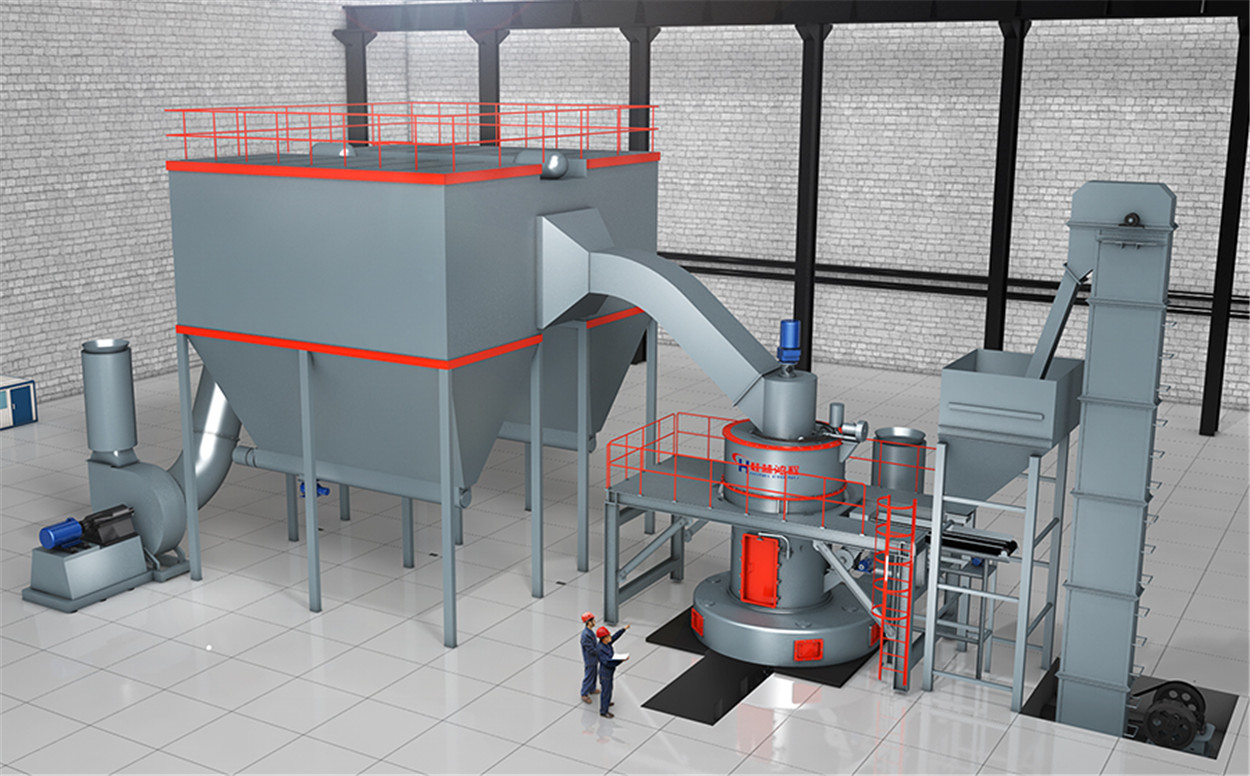

2. Vertical Coal Mill (HLM Verical Coal MidIcia):

Tlhahiso e phahameng, tlhahiso e kholo, sekhahla se tlase, tekanyo e phahameng ea tlhokomelo, tekanyo e phahameng ea ho kenella le Theknoloji e chesang ea Air. Kotsi e na le litšenyehelo tse phahameng tsa ho tsetela ebile e le sebaka se seholo sa mokato.

Litlhaloso le lipampiri tsa tekheniki tsa li-cals tsa hlm ha li lelera mail e halikiloeng (indasteri ea tšepe)

| Mohlala | Hlm1300mf | Hlm1500mf | Hlm1700mf | Hlm1900mf | Hlm2200mf | Hlm2400mf | Hlm2800mf |

| Bokhoni (T / h) | 13-17 | 18-22 | 22-30 | 30-40 | 40-50 | 50-70 | 70-100 |

| Mongobo oa lintho tse bonahalang | ≤15% | ||||||

| Product Bohle | D80 | ||||||

| Mongobo oa sehlahisoa | ≤1% | ||||||

| Power ea masapo a mapolanka (kw) | 160 | 250 | 315 | 400 | 500 | 630 | 800 |

Mothati oa I:CHo potlakisa thepa e tala

E kholoMashalaBoitsebiso bo sithabetsoa ke khatello ea ho fepa (15mm-50mmm) e ka kenang leloala la grand.

SethalaII: Grinding

E sithabetsengMashalaLisebelisoa tse nyane li romeloa ho hopper ea polokelo haufi le lifti, ebe o romeloa ka phapusing ea 'mila a ntse a tsamaea ka bongata le ka bongata ke ho itsamaela.

Mothati oa III:Khethollaing

Lisebelisoa tse halikiloeng ke sistimi ea grading, 'me phofo e sa tšoaneleheng e lokiselitsoe ke sehlopha sa khale mme e khutletse mochini o moholo oa ho rorisa.

SethalaV: Collection ea lihlahisoa tse felileng

Pofo e lumellana le khaello e phalla ka pipeline ka khase ebe e kenya mokalli oa khase bakeng sa karohano le pokello. Polao e felisitsoeng e rometsoe ho sehlahisoa sa sehlahisoa se phethiloeng ke sesebelisoa sa ho fetisa ka har'a koung e fetisang, ebe e kenngoa ke packer ea phofo kapa packer ea phofo.

Mehlala ea kopo ea ts'ebetso ea mashala ea mashala

Mohlala le palo ea lisebelisoa tsena: Likarolo tse 3 tsa HC1700 li bula potoloho ea potoloho ea potoloho ea Crinding mill

Ho sebetsana le litaba tse tala: anthracite

Ho fola ha sehlahisoa se felileng: 200 Mesh D92

Tsebo ea lisebelisoa: 8-12 lithane / hora

Morero ke ho fana ka mashala a manyane bakeng sa sekoti se tukang ka tlas'a lefatše ho li-Iiana Coal tsa sehlopha. Koranta e akaretsang ea morero ke China Academy ea China Academy ea mashala oa mashala. Ho tloha ka 2009, Sekoti sa Chaena sa Chaena e bile molekane oa leano la Coal ea Hongving ea Hongving le Alliance e matla. Metsotso eohle e lelekiloeng ea mashala le mashala a matla a mashala a amohela granding angovng granding mill bakeng sa ho tšoana. Lilemong tse 6 tse fetileng, Hongvng o sebelisitse lingoloa tsa mahlale a mashala, 'me merero ea mashala ea mashala e na le lijalo tse holimo ho hlahisa lijalo tsa sehlooho Chaena. Morero o etsa meralo e meraro ea li-raymond li-raymond minds tse nang le HC1700 e bulehileng tsamaiso ea potoloho, e etselitsoeng ka ho khetheha bakeng sa mashala a boreleli. Hc1700 ea likhahla li lula li le mashala tse bulehileng tse bulehileng ho bula potoloho, ho kenya sesebelisoa se phatlohileng le mehato e meng, 'me ho tšepahala. Tšu ea leloala la HC1700 e phahame ho feta ea mofuta oa setso sa pendulum e halikiloeng, e leng matla le tikoloho.

Nako ea poso: Oct-22-2021