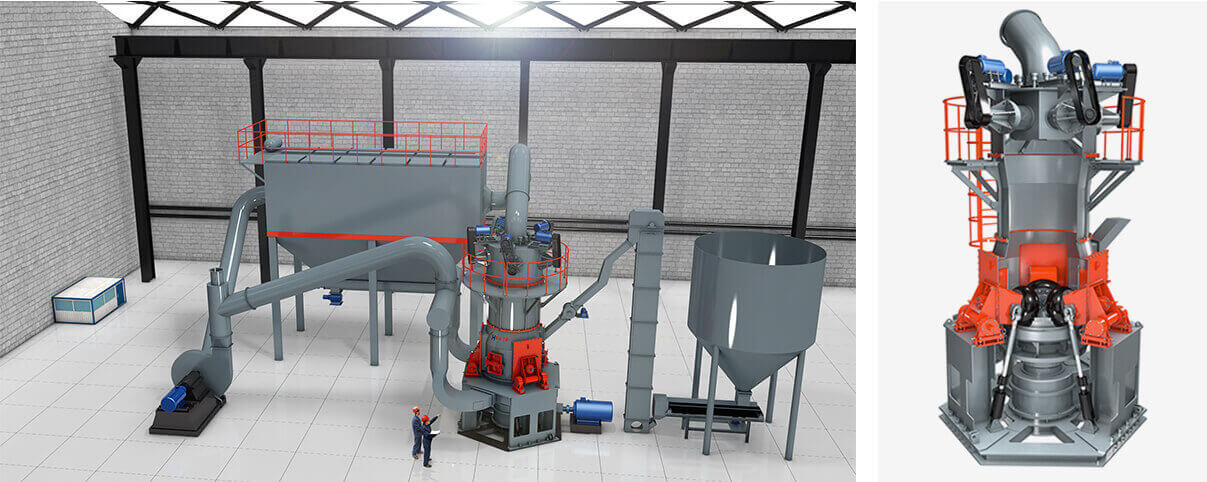

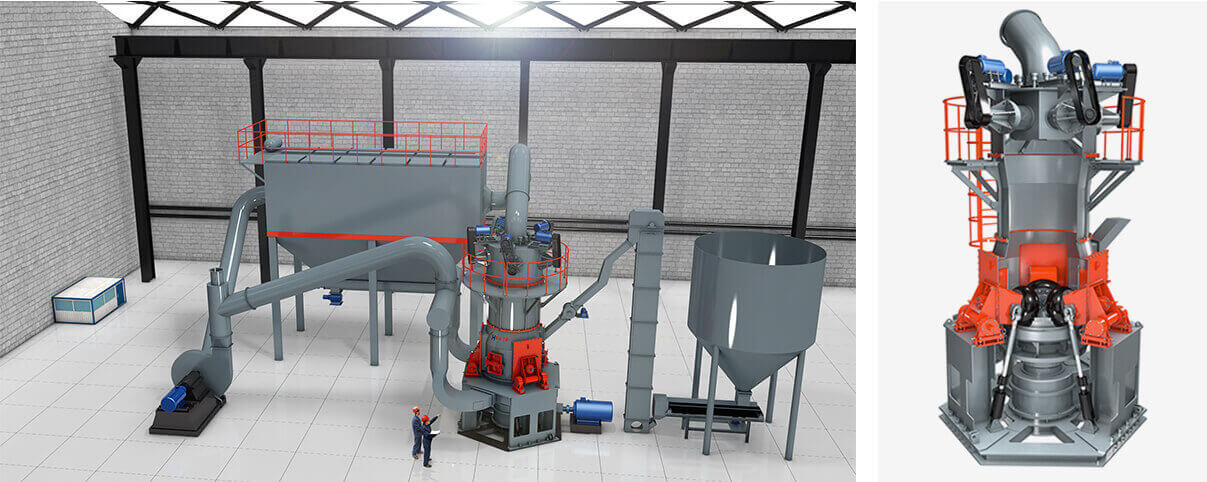

Structure and Principle

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Super Purchasing for China Factory Sell Directly Iron Ore Crusher and Gypsum Powder Unltrafine Vertical Roller Mill for Alumina Magnesium Oxide Silica Microstone Powder Factory, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for China Machine, Mining Machine, Our company covers an area of 20, 000 square meters. We have now more than 200 workers, qualified technical team, 15 years’ experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, make sure you do not hesitate to contact us.

As the HLMX 2500 Mesh Superfine Powder Grinding Mill works, the motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and smashed under extrusion, grinding and cutting. Simultaneously, the hot air is blew up around the dial and bring up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, and then, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

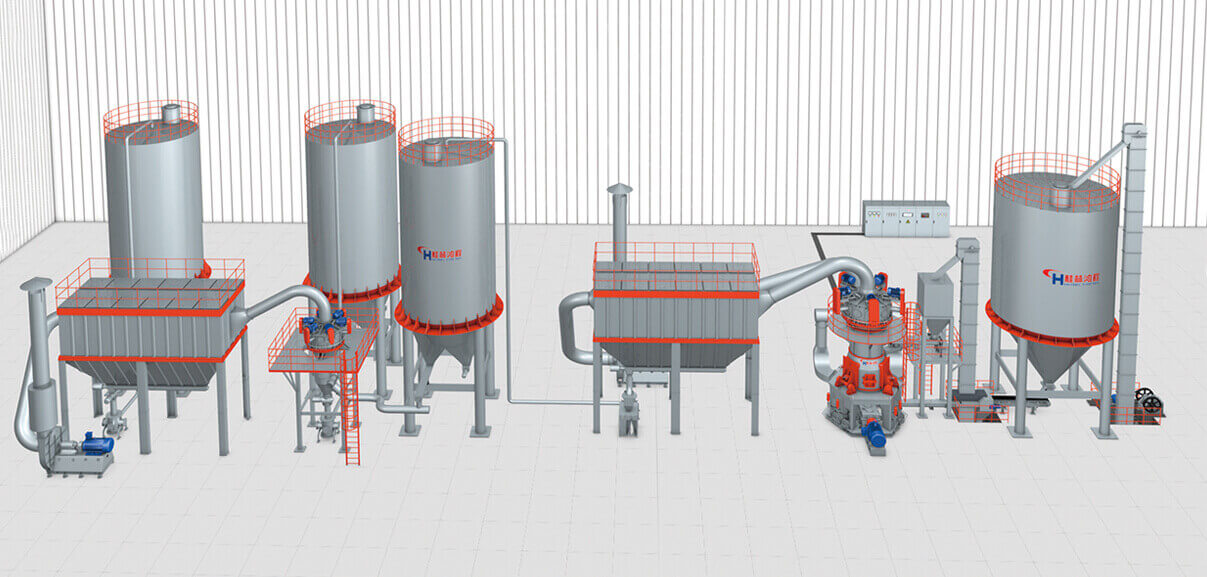

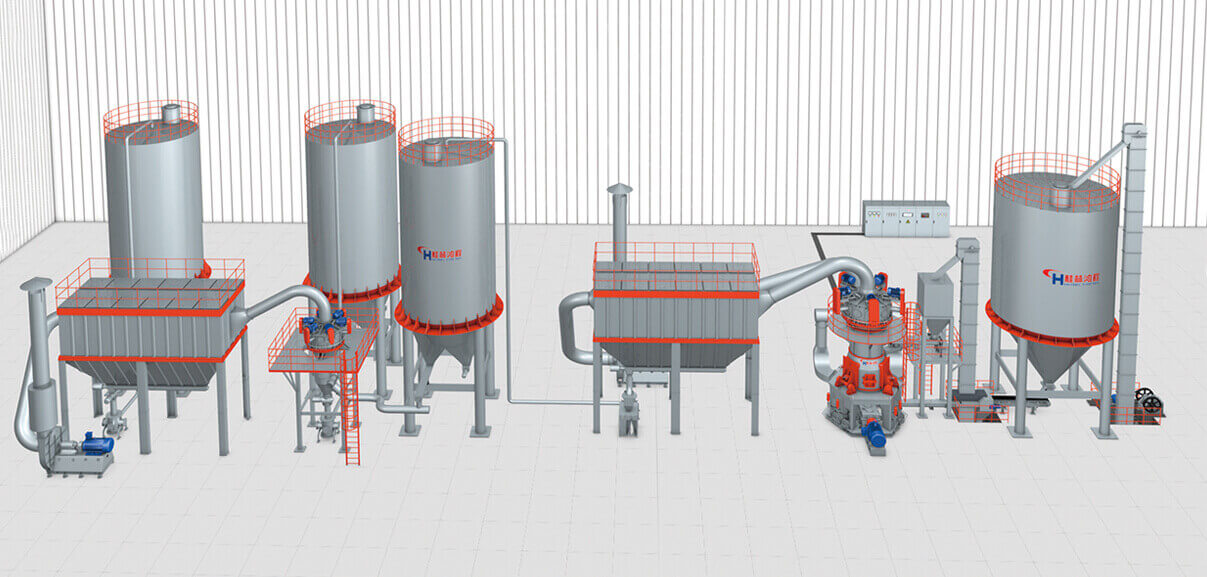

Secondary Classifying System

The secondary classifying system includes superfine classifier, fan, dust collector, hopper, screw conveyor and pipes. The classifier is the core machine of the whole system. HLMX series superfine vertical mill has equipped with the secondary classifier system, which is capable to efficiently separate coarse powder from fine powder to obtain products in different fineness between800 mesh to 2000 mesh.

Features of the secondary classifying system

High classifying efficiency: The classifier and the fan are controlled by frequency conversion speed regulation. By adjusting the speed of the classifier and fan impeller, various fineness of stable and reliable end product can be obtained rapidly. The classifying efficiency is high.

Classifier: A high efficient and energy saving powder separation device. Single rotor or multi-rotor is used to producing adjustable particle size due to the actual requirement.

Wide range of fineness: The classifying system is capable of selecting fine particles from the materials. The fineness can range from 800 mesh to 2000 mesh. With the secondary classifying system it can get different particles size, and it can also get same particle size in high throughput.

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Super Purchasing for China Factory Sell Directly Iron Ore Crusher and Gypsum Powder Unltrafine Vertical Roller Mill for Alumina Magnesium Oxide Silica Microstone Powder Factory, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Super Purchasing for China Factory Sell Directly Iron Ore Crusher and Gypsum Powder Unltrafine Vertical Roller Mill for Alumina Magnesium Oxide Silica Microstone Powder Factory, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.

Super Purchasing for China Machine, Mining Machine, Our company covers an area of 20, 000 square meters. We have now more than 200 workers, qualified technical team, 15 years’ experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, make sure you do not hesitate to contact us.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Super Purchasing for China Factory Sell Directly Iron Ore Crusher and Gypsum Powder Unltrafine Vertical Roller Mill for Alumina Magnesium Oxide Silica Microstone Powder Factory, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We’re on the lookout forward for your stop by for joint growth for Super Purchasing for China Factory Sell Directly Iron Ore Crusher and Gypsum Powder Unltrafine Vertical Roller Mill for Alumina Magnesium Oxide Silica Microstone Powder Factory, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.