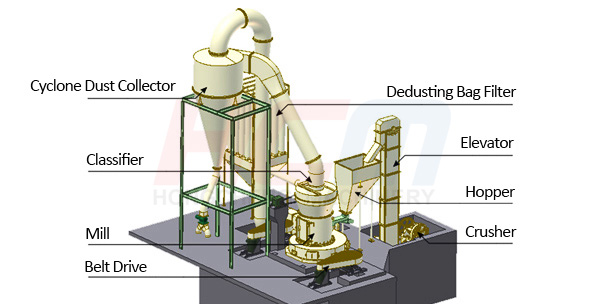

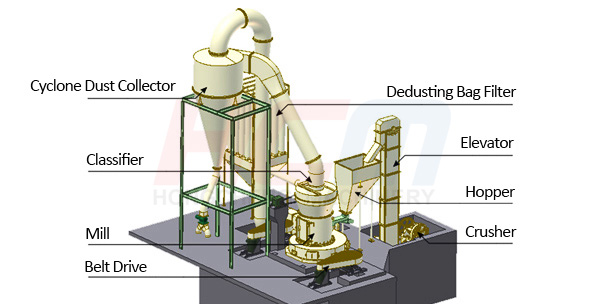

R-series roller mill is mainly composed of main mill, analysis machine, blower, bucket elevator, jaw crusher, electromagnetic vibrating feeder, electric control motor, finished cyclone separator and pipeline equipment, etc.

As the mill works, centrifugal force drives the rolls against the inner vertical surface of the grinding ring. Plows rotating with the assembly lift ground material from the mill bottom and direct it between the rolls and the grinding ring where it is pulverized. Air enters from below the grind ring and flows upward carrying fines to the classifying section. The classifier allows the sized material to pass to the product collector and returns unqualified oversized particles to the grinding chamber for further processing. The mill operates under negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the service life of major mechanical components.

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for Wholesale Discount Raymond Mill Alstom - R-Series Roller Mill – HCM, The product will supply to all over the world, such as: Finland, Namibia, Portugal, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.