Intshayelelo ye-calcite

I-Calcite yiminerali ye-calcium carbonate, ikakhulu eyenziwe yiCaCO3.Ngokuqhelekileyo iyabonakala, ayinambala okanye imhlophe, kwaye ngamanye amaxesha ixutywe.Ukwakhiwa kweekhemikhali zethiyori yile: Cao: 56.03%, CO2: 43.97%, ehlala ithathelwa indawo yi-isomorphism efana neMgO, FeO kunye neMnO.Ubunzima be-Mohs yi-3, ubuninzi be-2.6-2.94, kunye ne-glass luster.ICalcite eTshayina isasazwa ikakhulu eGuangxi, eJiangxi naseHunan.I-Guangxi calcite idume ngobumhlophe bayo obuphezulu kunye ne-asidi encinci enganyibilikiyo kwimarike yasekhaya.I-Calcite inokufumaneka kumntla-mpuma we-North China, kodwa ihlala ihamba ne-dolomite.Ubumhlophe ngokuqhelekileyo bungaphantsi kwe-94 kwaye umcimbi we-asidi onganyibilikiyo uphezulu kakhulu.

Ukusetyenziswa kwe-calcite

1.Ngaphakathi kwe-200 mesh:

Ingasetyenziswa njengezongezo ezahlukeneyo zokutya kunye nomxholo we-calcium ngaphezu kwe-55.6% kwaye akukho zixhobo ezinobungozi.

2.250 umnatha ukuya kwi-300 mesh:

Isetyenziswe njengezinto ezibonakalayo kunye nepeyinti yodonga lwangaphakathi nangaphandle lwefektri yeplastiki, i-rubber factory, i-coating factory kunye ne-factory material material.Ubumhlophe bungaphezu kwama-85 degrees.

3.350 umnatha ukuya 400 umnatha:

Isetyenziselwa ukwenza i-gusset plate, umbhobho we-downcomer kunye neshishini lemichiza.Ubumhlophe bungaphezu kwama-93 degrees.

4.400 umnatha ukuya kuma-600

Ingasetyenziselwa intlama yamazinyo, intlama kunye nesepha.Ubumhlophe bungaphezu kwama-94 degrees

5.800 umnatha:

Isetyenziselwa irabha, iplastiki, intambo kunye nePVC enobumhlophe obungaphezulu kwama-94 degrees.

6.Ngaphezu kwe-1250 i-mesh

I-Pvc, i-PE, Ipeyinti, iimveliso zebakala lokugquma, i-primer yephepha, i-paper surface coating, ubumhlophe obungaphezu kwama-95 degrees.Inobunyulu obuphezulu, ubumhlophe obuphezulu, ayinayo ityhefu, ayinavumba, ioli ecocekileyo, umgangatho ophantsi kunye nobunzima obuphantsi.

Inkqubo yokugaya iCalcite

Ukwenziwa komgubo weCalcite ngokwesiqhelo kwahlulwe kukwenziwa komgubo ocolekileyo wecalcite (20 mesh - 400 mesh), calcite ultra-fine powder deep processing (400 mesh - 1250 mesh) kunye ne micro powder processing (1250 mesh - 3250 mesh)

Uhlalutyo lwamacandelo ezinto ezikrwada ze-calcite

| CaO | MgO | Al2O3 | Fe2O3 | SiO2 | Ubuninzi bokudubula | Isalathiso somsebenzi wokucola (kWh/t) |

| 53-55 | 0.30-0.36 | 0.16-0.21 | 0.06-0.07 | 0.36-0.44 | 42-43 | 9.24 (Moh's:2.9-3.0) |

Inkqubo yokukhetha imodeli yomatshini weCalcite powder

| Ukucaciswa kweMveliso (umnatha) | 80-400 | 600 | 800 | 1250-2500 |

| Iskimu soKhetho lweModeli | R Series yokuSila Mill HC Series yokuSila Mill HCQ Series yokuSila Mill HLM nkqo Mill | R Series yokuSila Mill HC Series yokuSila Mill HCQ Series yokuSila Mill HLM nkqo Mill HCH Series Ultra-fine Mill | HLM nkqo Mill HCH Series Ultra-fine Mill+classifier | HLM Vertical Mill (+ classifier) HCH Series Ultra-fine Mill |

* Qaphela: khetha umatshini ophambili ngokwemveliso kunye neemfuno zokulunga

Uhlalutyo kwiimodeli zokusila

I-1.Raymond Mill, i-HC series pendulum grinding Mill: iindleko zotyalo-mali eziphantsi, umthamo ophezulu, ukusetyenziswa kwamandla aphantsi, ukuzinza kwezixhobo, ingxolo ephantsi;sesona sixhobo sifanelekileyo sokwenziwa komgubo wecalcite.Kodwa iqondo lomlinganiselo omkhulu lisezantsi xa lithelekiswa nelitye lokusila elithe nkqo.

I-2.HLM yokusila ethe nkqo: izixhobo ezinkulu, umthamo ophezulu, ukuhlangabezana neemfuno ezinkulu zemveliso.Imveliso inomgangatho ophezulu we-spherical, umgangatho ongcono, kodwa iindleko zotyalo-mali ziphezulu.

I-3.HCH i-ultrafine yokugaya i-roller mill: i-ultrafine grinding roller mill iyasebenza, igcina amandla, i-econga kwaye iyasebenza izixhobo zokugaya i-ultrafine powder phezu kwe-600 meshes.

I-4.HLMX i-ultra-fine vertical mill: ngokukodwa kwi-high-scale-scale production capacity ultrafine powder phezu kwe-600 meshes, okanye umthengi oneemfuno eziphezulu kwi-powder particle form, i-HLMX i-ultrafine vertical mill iyona nto ikhethekileyo.

Inqanaba I: Ukutyunyuzwa kwemathiriyeli ekrwada

Izinto ezinkulu ze-calcite zityunyuzwa sisityumsi ukuya kwi-feedness fineness (15mm-50mm) enokungena kwilitye lokusila.

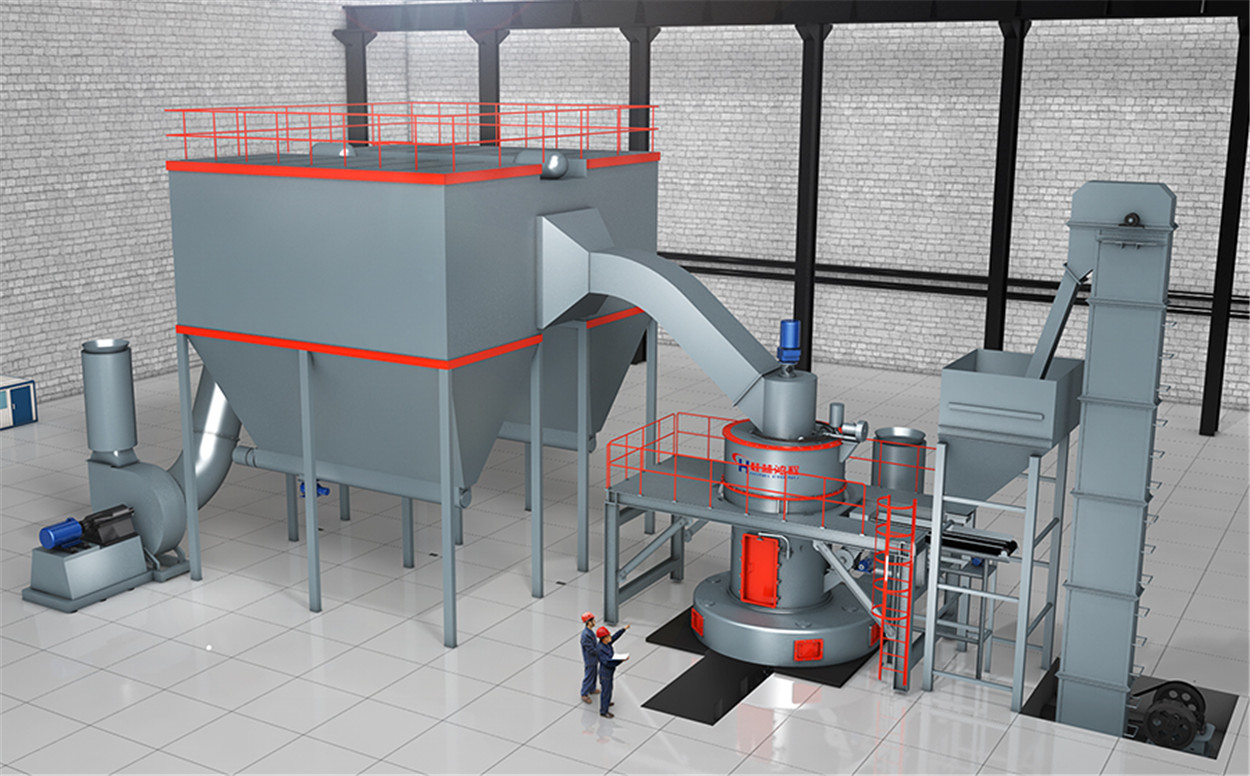

Inqanaba II: ukucola

Izinto ezincinci ze-calcite ezichotshoziweyo zithunyelwa kwi-hopper yokugcina nge-elevator, kwaye emva koko ithunyelwe kwigumbi lokusila le-mill ngokulinganayo kunye nobungakanani bomxhasi wokugaya.

Inqanaba III: Ukuhlela

Izinto ezigayiweyo zihlelwa yinkqubo yokulinganisa, kwaye ipowder engafanelekanga ihlelwe ngu-classifier kwaye ibuyiselwe kumatshini oyintloko wokugaya kwakhona.

Inqanaba V: Ukuqokelelwa kweemveliso ezigqityiweyo

Umgubo ohambelana nokucoleka uqukuqela kumbhobho onerhasi uze ungene kumqokeleli wothuli ukuze wahlulwe kwaye uqokelelwe.Umgubo ogqityiweyo oqokelelweyo uthunyelwa kwisisele semveliso egqityiweyo ngesixhobo sokuhambisa ngezibuko lokukhupha, kwaye emva koko upakishwe yipowder tanker okanye i-automatic packer.

Uhlobo lokusila olusebenzayo:

I-HC Series enkulu yokusila i-pendulum (ijolise kumgubo orhabaxa ongaphantsi kwe-600 mesh, enexabiso eliphantsi lotyalo-mali lwezixhobo kunye nokusetyenziswa kwamandla aphantsi)

HLMX Series superfine nkqo yokusila yokusila (Izixhobo zesikali esikhulu kunye nemveliso ephezulu inokuhlangabezana nemveliso enkulu.Ilitye lokusila elithe nkqo linozinzo oluphezulu.Izinto ezingeloncedo: ixabiso eliphezulu lotyalo-mali lwezixhobo.)

I-HCH ring roller ultrafine mill (Imveliso ye-ultra-fine powder ineenzuzo zokusebenzisa amandla aphantsi kunye neendleko zotyalo-mali oluphantsi lwezixhobo.Ithemba lemarike le-roller enkulu ye-ring-scale lilungile.Izinto ezingeloncedo: imveliso ephantsi.)

Imizekelo yokusetyenziswa kwe-calcite powder processing

Ukusetyenzwa kwezinto:calcite

Ukulunga:325mesh D97

Umthamo:8-10t/h

Uqwalaselo lwezixhobo:1set HC1300

Ukuveliswa kwepowder kunye neenkcukacha ezifanayo, ukuveliswa kwe-hc1300 phantse iitoni ezi-2 eziphezulu kunomatshini wendabuko we-5R, kwaye ukusetyenziswa kwamandla kuphantsi.Yonke inkqubo izenzekela ngokupheleleyo.Abasebenzi kufuneka basebenze kuphela kwigumbi lolawulo eliphakathi.Umsebenzi ulula kwaye wonga iindleko zabasebenzi.Ukuba iindleko zokusebenza ziphantsi, iimveliso ziya kukhuphisana.Ngaphezu koko, lonke uyilo, isikhokelo sofakelo kunye nokugunyaziswa kwayo yonke iprojekthi isimahla, kwaye saneliseke kakhulu.

Ixesha lokuposa: Oct-22-2021